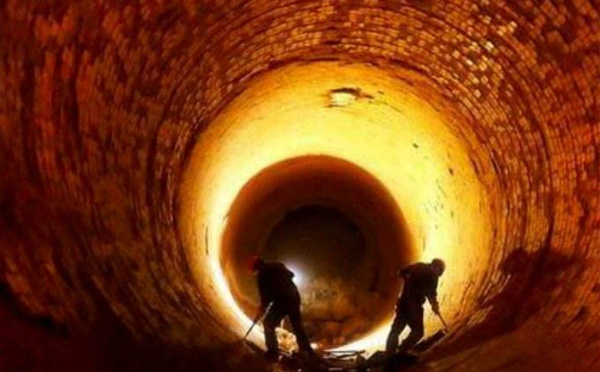

Cement rotary kiln is overall requirement:

Rise fight stability of aggressivity, thermal shock and wearability

① rises fight erode. Join chromium of carborundum, zirconia, oxidation and aluminium magnesium pointed spar to wait, reduce air hole.

② increases thermal shock stability. Logical choice manufactures technology, make air hole distributings reach intensity to be helpful for alleviating stress, prevent crackle to diffuse.

③ raises wearability. The choice has the stuff of intensity of medium, loud tepid voice, reduce the critical size of material.

④ changes construction way. Introduce take its natural course pouring makings, spray makings, explosion proof is pouring makings and hot rigid material.

Rise fight stress ability, increase high temperature strength,

Increase heat preservation performance,

Compound brick, insulation material,

Science, reasonable brick, accurate brick over all dimension,

Bricky build by laying bricks or stones is built.

Obligate expands seam: Use fireclay and paperboard correctly,

Bricky use,

The roast, cooling, skin that hang kiln, safeguard kiln skin to wait.

1, magnesian - brick of iron aluminium pointed spar

Raw material: High pure magnesia and iron aluminium pointed spar;

Craft: Reasonable grading, high pressure shapes, strict control is firing temperature and firing atmosphere;

Characteristic: ? Is personal Mei graceful rise abruptly deceive of courtyard of ㄐ of discuss of of green awake of Nao of ⒏ of bath of ㄐ of discuss of snipe of day of the leg that hold a courtyard in the palm?

Soft temperature of carry on one's shoulder performance of the tall, skin that hang kiln is superior.

2, magnesian calcic brick

Magnesian calcic brick is by the magnesian calcium of to calcine arenaceous the alkalescent and fireproof material that makes, normally CaO content achieves 40% above,

Basically use at rotary kiln firing belt.

Stick the reason of kiln skin easily:

The C2S in the grog when 1450 ℃ of ① (melting point 1900 ℃ ) produce chemical reaction with the CaO in the brick, in the brick

C3S is generated on the interface (melting point 2130 ℃ ) , form solid and stable kiln skin;

② CaO and clinker reaction raised the viscosity of fuse-element, clinker fuse-element is difficult the interior that penetrates a brick, thereby

Reduced a brick corrode flake, stabilized kiln skin;

③ because kiln skin is thick, firebrick surface thermal drop is small, endured thermic load and chemistry are eroded reduce,

At the same time the quantity of heat of kiln wall be lost decreases.

Problem: How to solve the production, to hydrate problem in store and using a process.

3, magnesian zirconium brick

With electric frit magnesia, zirconium Ying Sha is main raw material, classics high pressure shapes, high temperature is firing and make. The structure is compact, stomatic small and distributing intensity of even, high temperature stability of big, thermal shock is good, fight alkaline aggressivity and function of the skin that hang kiln exceedingly good, those who apply to cement rotary kiln is firing belt.

4, brick of magnalium pointed spar

With high pure magnesia and complex magnalium pointed spar are main raw material, advocate brilliant photograph is spar of square magnesian Shi Hejian, have be able to bear or endure goodly erode, fight flake reach high temperature resistant wait for a characteristic, can be used at rotary kiln of large cement working a way transfer belt.

5, silicon not wear-resisting brick

It is main raw material with fancy tall aluminous aluminous grog, carborundum and metallic silicon, classics high pressure shapes, high temperature is firing and make. Normal temperature and high temperature intensity stability of big, thermal shock is good, ceaseless in use process it is good to form covering layer, wearability reach fight flake the gender is strong, next transition that what apply to cement kiln the place such as mouth of belt, cooling zone, kiln.

6, fight flake tall aluminous brick

It is main raw material with fancy tall aluminous aluminous grog, through joining zirconium the photograph such as Ying Sha, cyanite, andalusite changes raw material, raise its to fight ability of thermal shock stability. Have fight flake capability is strong, fight potassium, natrium, sulfur, chloric reach alkalescent salt erode, the function such as rate of low heat conduction, it is cement kiln transfers belt and the good material that distribute ungird, still can use at the place such as the wicket cover of cement kiln, cooling machine.

7, alkali resistance brick, alkali resistance is pouring fiber of makings, steel increases fireproof and pouring makings

Brick of ① alkali resistance: Alkali resistance brick shows with low aluminium saggar, silica, Jiao Baoshi, useless porcelain and right amount additive are given priority to want raw material to be made. The product has volume stable, fight alkaline erode ability strong, be able to bear or endure permeate wait for a characteristic. The intake air heater that is used at cement kiln, disclose the position such as furnace, tertiary air canal.

② alkali resistance is pouring makings: Alkali resistance is pouring makings department pledges with siliceous aluminium material makes fireproof aggregate and powdery material, what make up with mud of aluminous acerbity brine and additive is pouring makings. Have good high temperature capability and alkali resistance to erode performance, excel in still have strength tall, wearability is good, can be in large and medium-sized use in the system such as canal of zephyr of intake air heater of kiln of dry method cement.

③ steel fiber increases fireproof and pouring makings: Wait to expect for aggregate and pink with tall aluminous aluminous grog or corundum, join bond and fiber of right amount heat-resisting stainless steel to have strength tall, tenacity thermal shock stability is good, good, fight flake and the characteristic with strong wearability. Use at cement rotary kiln kiln mouth, cooling machine, disclose the position such as furnace, intake air heater.

8, kiln mouth and gush coal canal are special and pouring makings

With andalusite, carborundum, corundum, high grade alumina, α- Al2O3 and SiO2 small pink is main raw material, make bond with CA-71 cement and join efficient the additive such as the agent that decrease water, have good heatproof shake steady performance, fight erode function, alkali resistance function and high temperature bulk to stabilize function, use at cement rotary kiln the place such as canal of coal of kiln mouth, gush.