Rubbish incinerator divides: Dream of type of comb with a double-edged fine-toothed comb of incinerator of city life rubbish, intermittent type incinerator, furnace burns furnace, rubbish platoon of incinerator of rubbish of industry of incinerator of hot solution aerification, fluid-bed type incinerator, rotary kiln type, furnace incinerator.

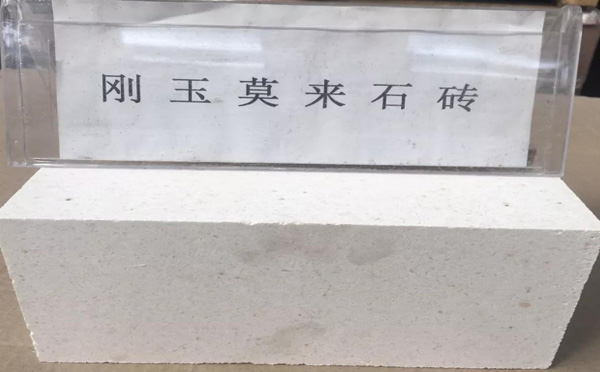

Incinerator mixes with firebrick of fireproof material cent pouring makings two kinds: Firebrick basically is mixed with argillaceous brick, tall aluminous brick carborundum brick is given priority to. Pouring makings pledge in order to stick earthy, tall aluminium but plastic with clay qualitative, carborundum pledges pouring makings give priority to. Because rubbish incinerator aggressivity is big, use pouring makings also be in ceaseless evolution, pledge with carborundum pouring tall aluminium of makings and phosphatic union is pouring makings increasing gradually, because of these two kinds pouring makings have good wear-resisting caustic sex.

The use temperature of rubbish incinerator is in 1200 ℃ - 1400 ℃ . The gas when burning is right be able to bear or endure the aggressivity of material is stronger, hearth, propeller, side wall wears away and concussion sex is very big. So, the choice actors or actress qualitative liner also will change ceaselessly.

But, to be able to bear or endure the requirement of material must have the following:

One, with intensity the product with tall, strong wearability, will resist wear away and of strong air current erode;

2, must have acid-proof sex and stability, will resist acidity is eroded;

3, thermal shock sex also is the main factor that cannot ignore;

4, should have CO to erode, prevent lining material to burst apart;

5, choose heat-insulating material, want a foundation different situation, the capable person that selects light-duty heat insolation to fit each position more is qualitative.

Anyhow, choose manufacturer of material majority user to be able to choose clay brick, tall aluminous brick, SIC brick, pouring expect and but plastic, if be the place of bed of going from place to place of incinerator of type of bed of going from place to place, must use wear-resisting first, fight basic material.

If be circumgyrate type incinerator, because ceaseless circumgyrate litter can cause temperature to change ceaselessly, get the product that uses wear-resisting, heatproof shock first, choose argillaceous brick, tall aluminous brick, SIC brick, SIC pouring makings.

Other nevertheless furnace incinerator is to choose clay, tall aluminium more qualitative, carborundum is qualitative pouring makings and tall aluminium are qualitative but plastic give priority to.

Fluid-bed incinerator is a kind when home applies relatively extensive rubbish incinerator at present, burn in fluid-bed in the process that the technology uses, its flaming principle basically is the combustion that undertakes rubbish through shedding voice to change a technology, and have the aid of is arenaceous undertake safety deals with, achieve life rubbish to burn thereby medium conducts heat equably and complete flaming is final purpose, in the process that burns in rubbish, air can be entered from fluid-bed bottom gush, what realize arenaceous medium is reasonable churn, make rubbish forms sex drifting voice. Those who adopt fluid-bed incinerator technique apply, what can make sure bottom of the chamber of a stove or furnace is decorated adequately is high temperature resistant characteristic, and, systematic board remove theatrical makeup and costume has the inert particle that holds heat, make while the bed issues cloth wind inert grain amounts to the state that reveals boiling, form fluid-bed bed paragraph. Burn in fluid-bed in the process of rubbish, need undertakes rubbish broken place is buried, make rubbish achieves certain size status, and, the liquefaction that passes short time burns, can have the aid of lights wind action to undertake its handling inside short time, form the rationality of fluid-bed incinerator thereby.

In the process that uses in fluid-bed incinerator, its advantage basically reflects in the following respects:

The first, fluid-bed burns the efficiency of combustion furnace is opposite taller, when and did not burn matter eliminate to lead have 1% only.

The 2nd, in the aflame inside furnace, there is mechanical movement component inside furnace, and wear is relatively good, can prolong mechanical service life.

Defect:

The first, fluid-bed incinerator basically is the processing that relies on air to undertake rubbish and combustion, undertaking having the demand of granuality to entering the rubbish of furnace next, normally the circumstance enters the rubbish grain of furnace to cannot be more than 50mm, and the rubbish of big grain is thick can fall to hearth directly, achieve complete flaming thereby ultimate goal.

The 2nd, the condition with boiling inside furnace rubbish can rely on the air of high pressure of large wind force entirely, existing power consumption problem of grey generous of big, production, purify the negative charge with was brought fixed for downstream flue gas thereby.

The 3rd, fluid-bed incinerator is running the course that reachs an operation in, its professional technology is opposite taller, accordingly, optimize in adjusting control method kind, need has professional technical staff to undertake operating reaching introductory.

The boiler setting of rubbish incinerator is the main component of boiler, the chamber of a stove or furnace arrives since sealed, adiabatic, prevent grind, the anticorrosive, action that forms flue. The intensity that use fireproof data asks good volume is stability, good normally and good fireproof, adiabatic character. Rubbish burns because boiler burns rubbish water content is bigger and part is complex, rubbish contains a large number of caustic gas inside the high temperature flue gas of combustion generation, the material of low melting point in rubbish allows easy melt and adhere to go up in boiler setting, high temperature issues mobile rubbish or the bed makings inside fluid-bed furnace arises to wear away and be pounded to boiler setting, more incidental fireproof material and its support metal the problem of serious injury. Burn as rubbish efficient generate electricity the use that reachs aerification melt technology, rubbish burns flue gas temperature is higher, the chroma of gas of corrupt chaotic sex such as HC1, H2S increases, fireproof material use condition is more astringent, the heatproof shake sex with ask fireproof material is had better, acid-proof caustic and fight slaggy erode character, ask fireproof layer is had longer service life and more build and maintain cost of economy.

The temperature inside rubbish incinerator does not exceed 1400 ℃ commonly, boiler setting undertakes by fireproof layer, adiabatic layer, thermal insulation normally multilayer design, make boiler setting outside face temperature under 70 ℃ , can improve incinerator surroundings, reduce heat loss due to radiation. Rubbish burns boiler has special working environment, the working environment that should press different position asks to choose right stuff. Adiabatic layer and thermal insulation basically have adiabatic effect, adiabatic layer can rise to protect the action of thermal insulation at the same time, considering acid-proof caustic go up with the foundation of proper intensity, the thermal conductance that basically asks according to working temperature and design is chosen, the fireproof material that in be normally, pledge and pledges gently. Regard the fireproof layer of working layer as material, considering the base of working temperature, main basis is sex of wearability, heatproof shake, acid-proof caustic and fight slaggy erode character to choose.

According to differring the position of demand can choose the fireproof material of different function, fireproof layer respect basically is recommended those who use tall aluminium is fireproof and pouring makings, tall aluminium is pouring the fireproof temperature of makings is controlled in 1600 ℃ , be being used in fireproof layer also is most proper place, and sexual price is compared extremely tall, it is one of most right stuff; This respect recommends adiabatic layer quite use the acid-proof wear-resisting that pledges gently pouring makings, basically have the effect of heat preservation heat insulation. . . . . .

Fireproof and pouring makings construction method basically has pouring, pound dozen, the method such as spray, daub, differ by construction method normally but fractionize is different material. The spray that can use spray construction among them but plastic, it is good to have heatproof shake sex, fight slaggy erode, construction is easy wait for an advantage, get be popularizinged generally use in Japan in recent years, the fireproof material expect from high strenth is low qualitative heat-insulating material has application.