How many does common blaze temperature have? Belong to blaze commonly the outer flame of highest temperature also is controlled with respect to 500 ℃ , burn of course of material different, blaze temperature also is met different. So is Mo Laishi firebrick highest and fireproof how much is temperature limits? Mo Laishi firebrick allows fireproof temperature to should be in according to its check mark 1200 ℃ - 1700 ℃ left and right sides! What concept is this? The temperature of puddling is controlled in 1300-1500 ℃ commonly, and Mo Laishi firebrick is theoretic in proper time paragraph inside can withstand the test of molten iron.

The heat preservation effect of industrial kiln furnace is one of crucial factors that affect specific power consumption. Develop a kind of service life to grow and the product that can reduce quality of body of heater is very be necessary. MG-28 belongs to Molaishi light qualitative adiabatic brick, have high temperature capability the characteristic with good, low cost, can use at kiln furnace liner, can reduce body of heater effectively not only quality, managing light, still can prolong lining service life, reduce uphold charge.

1: MG-28 Mo Laishi pledges adiabatic brick is made gently

With industrial AL2O3 pink, clay, agglomeration good aluminous alumina and partial cyanite are given priority to want raw material, add wood chip (1mm is chosen) beg with polystyrene (diametical 2~0.5mm) preparation pledges gently brick. Composition of raw material chemistry sees, deserve to compare in undertake batch mixing. In joining fine white of industrial AL2O3 pink, aluminous, cyanite, clay mixer first, work mix 3~5min, add polystyrene ball, wood chip and bond next (adscititious) , edge border agitate, after mixing even, go out grind.

Use crowded mud law to shape. After 48h of ℃ of 50~60 of wet base course and 100~110 ℃ 72h are dry after shaping firing. Firing temperature control is in 1400~1500 ℃ , heat preservation 8h. The exterior that checks sample according to relative standard check and manage change target.

2 results and analysis

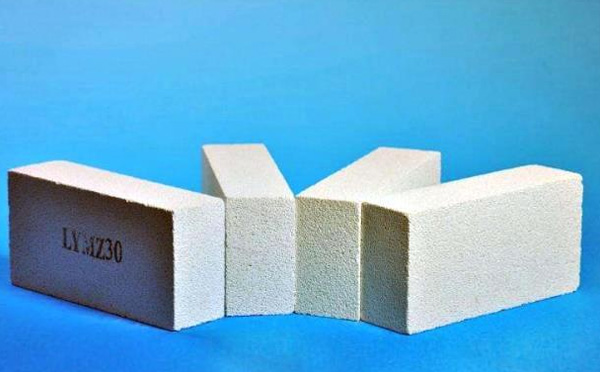

MG-28 Mo Laishi of production pledges gently exterior of adiabatic brick finished product is white, edges and corners trenchant, size is exact. Its manage changes index to be: AL2O3=67.99% , fe2O3 = 0.87% , bulk density is 0.8g·cm, compression intensity is 2.3MPa, change of the line after 1500 ℃ 8h is burned is —0.1% , thermal conductance (800 ℃ ) for 0.24W·m-1·K-1.

Turn index result according to manage knowable: Content of AL2O3 of finished product of light qualitative brick is 67.99% , explain this matchs more than generating Molaishi: Fe2O3 content < 1% , exterior of the adobe after be being burned so is white (if iron content on the high side, the adobe after burning is aglow) . Compression intensity satisfies a standard to ask (≥2.1MPa) , because industrial AL2O3 is in,be firing 13% bulk systole of the left and right sides arose in the process, those who be helpful for compression intensity rise. Clay and industrial AL2O3 are in firing the bulk that different level appeared in the process is contractive, and aluminous Molaishi changes generation bulk to expand, of cyanite decompose reaction to also produce bulk to expand, systematic bulk expands and systole offsets each other make change of product whole line not big, change of the line after 1500 ℃ 8h burns is only - 0.1% : Thermal conductance (800 ℃ ) for 0.248W·m-1·K-1, because the experiment is medium,basically be arose after added wood chip and polystyrene spherule are firing even small 7 aperture, constituent structure is even, thermal conductance is low, achieved energy-saving result.

The application of 3 products

The liner of job of shuttle type kiln that MG-28 Mo Laishi pledges adiabatic brick applies at ceramics works gently, 1400 ℃ control normal use temperature, high temperature resistant function of function, heat conduction function, accumulation of heat all compares cite data advantageous and service life is long, improved the quality of the product and productivity, improved working environment. Use the air consumption of every kiln after JM28—0.8 Mo Laishi pledges the brick is working line gently to be controlled for 160Kg, mix a structure than former brick every kiln but managing light 40Kg left and right sides, energy-saving advantage is clear.

This so say Mo Laishi firebrick its are fireproof function is really all wool and a yard wide still. Superhigh is high temperature resistant the first selection material that function also yields Mo Laishi firebrick to become kiln of high temperature furnace to build. And of Mo Laishi firebrick detect national level GB/T 35845-2018 " firebrick of Mo Laishi qualitative heat insolation " just carried out formally January 1 in 19 years. To what set in new standard each detect index, everybody still is not too familiar for certain, below small make up introduce in detail for everybody.

Above all, the name brand appraisal of Mo Laishi firebrick basically assigns a grade, basically be MG-23, MG-25, MG-26, MG-27, MG-28, MG-30, MG-32. Its add ratio of hot line change correspondingly to not be more than the experiment temperature of 2% to be 1230 ℃ , 1350 ℃ , 1400 ℃ , 1450 ℃ , 1510 ℃ , 1620 ℃ , 1730 ℃ .

Next, firebrick manage changes Mo Laishi detect index basically has strength of compression of density of alumina content, ferric oxide content, bulk, normal temperature, heat permanent line changes temperature of bate of loading of rate, coefficient of thermal conductivity, 0.05MPa, fight flake the index such as function. The property of high temperature creep that needs the Mo Laishi firebrick that point out and density measure the key of its quality performance to be in, and its detect correspondingly index is namely heat ratio of permanent line change and bulk density these two index.

The expensive aluminous simple fireproof stuff that pledges Mo Laishi brick gives priority to brilliant photograph gently, effect of weight light heat preservation is good, it is makings of high grade high pure and fireproof pink, press product demand proportion, 0.8-1.0 uses many, general alumina content is in 65% ~ 75% between. Mineral composition divides Molaishi outside, contain alumina among them inferior person still contain a few glass photographs and Fang Shiying; Contain alumina taller person still contain a few corundum.

Light qualitative Molaishi the brick is main raw material with tall aluminous aluminous grog, join a few clay or unripe alumina to make bond, via shaping, firing and make.

Bricky application goes to light qualitative Molaishi there is the following advantage among kiln furnace.

Light qualitative Molaishi the hot coefficient of expansion of bricky goods is very small, thermal conductivity is tall, heat-resisting shake performance is good, high temperature intensity is high. Use for a long time below high temperature also not bate, do not suffer any acid-base erode, have the good performance that fight salt, also do not get metal and slaggy benefit wet, qualitative light, be high grade high temperature resistant material.

But pledge Mo Laishi brick oxidizes easily below high temperature gently, unfavorable use in oxidation atmosphere. Bricky goods uses light qualitative Molaishi extensively at lining of high temperature furnace (bottom of hearth, crucible, shaft) , the liner of furnace of fusion nonferrous metal. Goods of Mo Laishi brick can make reaction chamfer and petro-chemical high-pressured boiler liner.

Characteristic of light qualitative Mo Laizhuan:

1. low heat conduction, low thermal capacitance.

2. purity tall, matter content is little.

3. is high temperature resistant, can contact blaze directly.

4. intensity is high, have good heatproof shake performance.

Light qualitative Molaishi the brick is applicable: Applicable metallurgy, petrifaction, building materials, pottery and porcelain, all sorts of industry furnace of the industry such as machinery heat up face liner and back line. Be like: Splitting decomposition furnace, change furnace, add shrinkage fitting buy, fine device, second birth device, hot-blast stove, heating furnace, soaking furnace, heat treatment furnace, resistor furnace, channel kiln, roller path kiln, the bell overspreads kiln, vitreous pool kiln.

Next, exterior of Mo Laishi firebrick and tolerance detect index is measure of main and visible account, permissible variation in dimension, screwy diameter of length of deviation, vertex damage, edge damage length, cave, grain cracks length, opposite side to differ. Notable is, to a few distinctive model its allow Mo Laishi firebrick it is OK that grain cracks length according to supply and demand two decide come from an agreement.

The brick has Mo Laishi firebrick and corundum Mo Laishi creep of tall, high temperature leads loading bate temperature sex of low, heatproof shake is good wait for an advantage, apply extensively at kiln of frit of blast furnace hot-blast stove, glass, dry extinguish anxious reach heating furnace to wait for industrial furnace on kiln. Mo Laishi is fireproof firebrick is eroded easily below high temperature by alkalescent firebrick. In addition, below high temperature, mo Laishi can generate Al2O3 by reaction with vapor and be damaged.

Accordingly, mo Laishi firebrick is unfavorable the environment that reachs Gao Shuizheng to enrage content in tall basic slag falls to be used for a long time.

Outside the compound and fireproof firebrick that forms besides Molaishi and it and corundum, mo Laishi is OK still form firebrick with other data in order to improve its performance, firebrick of the Mo Laishi that be like zirconium, Molaishi - carborundum firebrick. Firebrick of alleged zirconium Mo Laishi is Molaishi - zirconia composite material. But because zirconia price is high, in actual production middling passes Al2O3 or alumina and zirconium stone reaction make grog of the Mo Laishi that get zirconium or firebrick.

The production method of this kind of firebrick and raw material includes electric frit law and agglomeration method. The aluminous zirconium silicon that makes with electric founding (we are in AZS) firebrick already discussed in brick of corundum of electric frit zirconium. Make Al2O3 and ZrSiO4 burden to calcine grog of the Mo Laishi that get zirconium, again its broken, mix practice, shape with firing make firebrick of the Mo Laishi that get zirconium, namely agglomeration AZS brick.

With agglomeration or electric frit Molaishi is the firebrick that main raw material makes, can use Molaishi entirely, also can use Molaishi partly, the part uses corundum to be raw material. Former call Mo Laishi firebrick, latter calls corundum to not come stone firebrick or corundum Mo Laishi brick. The manufacturing technological process of Mo Laishi firebrick and tall aluminous brick are identical, burden classics batch mixing, shape, dry with firing wait for a few working procedure. Firing the purity of temperature and burden composition, raw material and the requirement to firebrick function are concerned, it is 1500 ~ normally 1700 ℃ .

Basically use at lining of blind angle of system of splitting decomposition of kiln of agglomeration of regenerator of kiln of frit of shaft of hot-blast stove roof, blast furnace and hearth, glass, pottery and porcelain, oil to wait.