N-1 clay brick is fireproof degree keep abreast of with silica brick, achieve 1690~1730 ℃ , but load molten is spent lower than silica brick however 200 ℃ left and right sides. Contain because of be being divided in argillaceous brick tall fireproof outside body of spent Mo Laishi crystallization, still contain press close to photograph of sandwich glass of noncrystalline of dot of one most low dissolve.

Limits is spent in the of 0~1000 ℃ in, the cubage of argillaceous brick subsequently is spent rise and well-balanced splash goes up, linear expansion graph is approximate at this parallel, linear expansion rate is 0.6%~0.7% , can the half left and right sides of silica brick.

Spend when after amounting to 1200 ℃ , carry again again lukewarm when, its volume goes up You Peng highest value just began furl. The rudimental furl of argillaceous brick causes the pine that fill wall ash seams to crack, it is the one whole blemish of argillaceous brick. Spend when after exceeding 1200 ℃ , the low dissolve in argillaceous brick orders thing slowly melt, suffer interfacial tension effect because of grain content and mutual between lean too closely, cause cubage furl then.

Of N-1 clay brick mineral making a key is kaolinite (Al2O3·2SiO2·2H2O) with 6%~7% residual (the oxide of potassium, natrium, calcic, titanium, iron) . The fire whole process of argillaceous brick, the key is kaolinite lasts moisture is deliquescent change into Molaishi (3Al2O3·2SiO2) the whole process of crystallization body. The SiO2 in argillaceous brick and Al2O3 are in fire whole process with residual generation in all the aluminous silicate that brilliant low dissolve nods, surround greatly crystallize in Molaishi body is circumjacent.

Handicraft of material of fire prevention of acidity of vest in of N-1 clay brick, can resist soda acid sex is slaggy with system of steam of soda acid sex corrode, the resistance of alkaline to slanting chemical material is a bit weak. The hot character of argillaceous brick is good, be able to bear or endure urgent cold urgent heat.

N-1 clay brick, argillaceous brick is crucial by Molaishi (photograph of 25% ~ 50%) , sandwich glass (25% ~ 60%) and calcite and calcite (achieve 30% ) be formed. It is raw material with good model clay commonly, beforehand calcination autumn expects, deserve to go up subsequently soft model clay, with working a way partly may model law figuration, is spent in handicraft of brick of clay of fire of 1300 ~ 1400 C. The shirt-sleeve agent make it such as the siliceous natrium that still can add grain, concrete did not burn handicraft and adventitious raw material. Of the application of the common corundum brick in the fire kiln of the application that this is heating furnace of puddling blast furnace, hot-blast stove, hot-blast stove, driving force, limekiln, machinery, china and corundum brick and relevant firebrick and relevant firebrick.

Handicraft of material of fire prevention of acidity of argillaceous brick vest in, can resist soda acid sex is slaggy with system of steam of soda acid sex corrode, the resistance of alkaline to slanting chemical material is a bit weak. The hot character of argillaceous brick is good, be able to bear or endure urgent cold urgent heat. Of argillaceous brick fireproof degree keep abreast of with silica brick, achieve 1690~1730 ℃ , but load molten is spent lower than silica brick however 200 ℃ left and right sides. Because be divided in argillaceous brick,contain tall fireproof outside body of spent Mo Laishi crystallization, still contain press close to the photograph of sandwich glass of noncrystalline of low dissolve dot of one most.

Limits is spent in the of 0~1000 ℃ in, the cubage of argillaceous brick subsequently is spent rise and well-balanced splash goes up, linear expansion graph is approximate at this parallel, linear expansion rate is 0.6%~0.7% , can the half left and right sides of silica brick. Spend when after amounting to 1200 ℃ , carry again again lukewarm when, its volume goes up You Peng the value just began furl. The rudimental furl of argillaceous brick causes the pine that fill wall ash seams to crack, it is the one whole blemish of argillaceous brick. Spend when after exceeding 1200 ℃ , the low dissolve in argillaceous brick orders thing slowly melt, suffer interfacial tension effect because of grain content and mutual between lean too closely, cause cubage furl then.

Argillaceous brick makes cerebral surgical department with argillaceous cement grog, the Al2O3 water content that saggar makes shirt-sleeve agent make it is 30 ~ the handicraft of fireproof insulation material of 48 % . Argillaceous brick is historical time long, use general fireproof insulation material. How much is of according to aluminous water content, 55 call clay followingly the brick, it is this kind of neutral turns fireproof insulation material, by aluminous alumina or water content of other ferric oxide taller raw material makes make it form burn what build and become. Have hear resistance tall, material spends fire prevention to fluctuate in 1700°C, li of line of heating furnace of rotary kiln of furnace of dissolve of sandwich glass of in order to, cement, puddling. Also have probably certain have Gao He soft, low stress is flabby, low the brick of tall aluminous clay that gives air hole, handicraft of tall aluminous brick, must make in production according to different application in be aimed at raw material make up want a key only. And tall aluminous brick and argillaceous brick are ferric oxide water content not only is different, close of their manufacturing technological process, but be in condiment,the mix into of cement grog is added taller, can exceed 90-95% , fire is spent taller than argillaceous brick also a lot of, measure in specific check in of major in order to of brick of tall aluminium of one 2 class spends the channel kiln in 1500-1600°C, the furnace of a lot of kiln such as the line in puddling blast furnace, roof, reverberator, machinery.

The raw material that produces production clay brick is clay pledges mineral. Pure natural saggar can be divided into good model clay and soft model clay normally. In fireproof insulation material production makes treatment in craft, both much regards cement as clinker after classics calcination; From the back after one kind turns on the water, plasticity has been out of shape, very easy to calcine, serve as shirt-sleeve agent more.

Clay mineral key has kaolinite (Al2O3·2SiO2·2H2O) , ground opens stone (component and kaolinite are same, constant of Dan Jing case is different) , cheat stone (Al2O3·4SiO2·6H2O) and biotite kind mineral.

Stick rich and colorful of raw material of earthy and fireproof insulation material, production is machined brief change, cheap of qualitative actor price, compare consequently other all fireproof insulation material apply more generally: Blast furnace of puddling of in order to, hot-blast stove, cupola, bucket flourishing steel and software of the system that irrigate steel and soaking furnace, hot-blast stove, furnace of rare metal fusion, aluminous silicate industry is produced and chemical industry reachs his with kiln furnace the chimney of equipment of all and adiabatic machine and smoke evacuation path.

Argillaceous brick suitable scope:

Building materials of metallurgical industry of general in order to, adornment, chemical plant, crude oil, mechanical equipment is made, the industry such as aluminous silicate, driving force produces an industry.

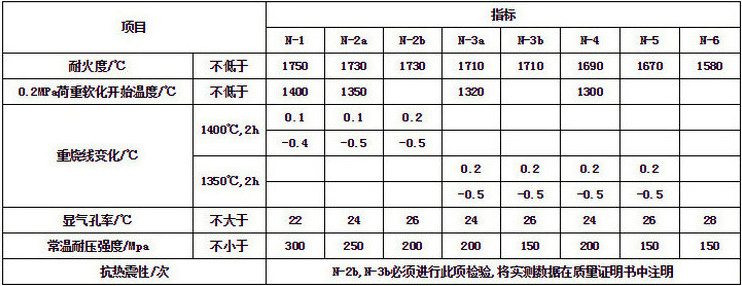

Manage changes target: