The definition of tall aluminous brick:

Tall aluminous brick according to 3 oxidation cent of content of 2 aluminous Al2O3 makes 4 order and degree: Content of Al2O3 of ─ of Ⅰ class ─ > 75% ; Content of Al2O3 of ─ of Ⅱ class ─ is 60 ~ 75% ; Content of Al2O3 of ─ of Ⅲ class ─ is 48 ~ 60% ; Fancy content of Al2O3 of tall aluminous brick is 80% ; Content of alumina of tall aluminous brick is in 48% above are to belong to neuter and fireproof material. By alumina or other alumina content taller raw material classics shapes to be become with to calcine. Thermal stability is tall, fireproof degree in 1770 ℃ above. The sex that fight broken bits is better, the liner that is used at build by laying bricks or stones to build furnace of circumgyrate of forge of steel-making electric stove, glass, cement to wait. This product has decrescent of high temperature squirm, fight aggressivity stability of strong, thermal shock is good wait for an advantage, apply to big, medium-sized hot-blast stove. Tall aluminous brick and the manufacturing technology of many clinker clay brick are similar, different point depends on scale of the grog in burden taller, can be as high as 90 ~ 95% , clinker is in broken before need to classification choose and screening divide iron, firing temperature is higher, if the tall aluminous brick such as Ⅰ , Ⅱ uses channel,1500 ~ are commonly when kiln is firing 1600 ℃ .

Melting point of tall aluminous brick:

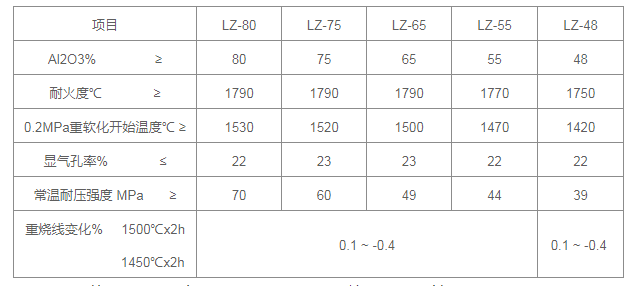

The composition index of product of tall aluminous brick cannot express to describe it to be able to be burned according to melting point the temperature of frit, because tall aluminous brick is to belong to inorganic metalloid material to be only below constant intensity of pressure,produce metabolic temperature, , it is the product of a kind of branch of firebrick, cent is 4 grade, fancy 80, one class 75, 2 class 65, 3 class 55, among them 0.2MPa loading bate begins temperature ℃ to be in respectively: 1530, 1520, 1500, 1450.

Tall aluminous brick and soft:

Tall aluminous brick is fireproof the relation of temperature and alumina content

1, alumina content ≥50% , fireproof temperature ℃ > 1770 degrees, ℃ of loading bate temperature is in 1420 degrees of;

2, A1203 content ≥60% , fireproof spend ℃ > 1770 degrees, ℃ of loading bate temperature is in 1460 degrees of;

3, alumina content ≥70% , fireproof spend ℃ > 1790 degrees, ℃ of loading bate temperature is in 1510 degrees of;

4, A1203 content ≥82% , fireproof temperature ℃ > 1790 degrees, ℃ of loading bate temperature is in 1550 degrees of;

5, A1203 content ≥90% , it is corundum brick, fireproof temperature is 1900 degrees, temperature of bate of the loading below 0.2Mpa is 1700 degrees.

Function of tall aluminous brick:

1, fireproof degree. Goods of tall aluminous brick is the high variety in products of siliceous aluminous simple fireproof data, its fireproof degree along with Al2O3, the addition of content and rise, general not under 1750—1790 ℃ . If Al2O3 content is more than the corundum brick of 95% , fireproof degree can be as high as 1900-2000 ℃ .

2, thermal shock stability. In goods of tall aluminous brick, when firebrick temperature changes, because expand,difference brings about stress concentration. So, the thermal shock stability that goods of tall aluminous brick compares argillaceous brick product is poor, general water-cooling frequency has 3—5 only second.

3, loading bate temperature. The addition that the loading bate temperature of goods of tall aluminous brick follows 2 oxidation silicon and content of alkali metal oxide and reduce, but taller than argillaceous brick goods, it is 1420—1530 ℃ about. Al2O3. Content is more than the corundum brick of 95% , temperature of its loading bate can amount to 1600 ℃ above.

4, the sex that fight broken bits. As a result of the 3 oxidation in goods of tall aluminous brick 2 aluminium are shown neuter and content is high, products of this kind of data is so basic to acid of slag erode all have counteractive capacity.

5, the heavy change that burn a line. If of goods of tall aluminous brick firing temperature is enough, firing time is enough, criterion volume is steady, small; of the heavy change that burn a line conversely, if the remains of argillaceous brick goods is contractive,arise, the reason also is to produce recrystallization be caused by.

Index of composition of tall aluminous brick: