Fireproof material chooses cupola liner

The crucible that water-cooling furnace uses extensively is pounded dozen of makings and pouring makings, belong to the advanced and fireproof material that is aggregate with material of element of corundum, carborundum, carbon, among them carborundum content is higher, of material fireproof degree, stoving density, thermal conductivity is taller.

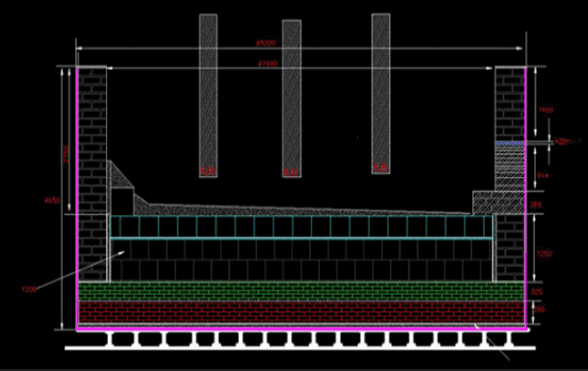

Lining material should erode characteristic choice according to the structure of cupola and lining. As a result of medium or small the crucible space of cupola is lesser, disadvantageous the construction that expects at undertaking pounding hitting, because this crucible uses carborundum brick build commonly, the surface is used advanced pound dozen of makings pouring perhaps makings. Taphole, taphole needs to use what make with advanced and fireproof material to shape commonly brick. The crucible of large cupola and taphole can be used completely advanced pound dozen of makings pouring perhaps makings build, inside water-cooling wall need not build lining.

To assure the temperature of earlier iron fluid, medium or small cupola water-cooling fusion paragraph interior can use common clay brick thin lining of build of common perhaps and fireproof mud.

The furnace life that the fireproof material in crucible and its build ply should ask according to cupola place is affirmatory, if ask furnace life is longer,choose fireproof the advanced and fireproof stuff with low rate of degree of corrode of tall, dip, use thicker lining lining at the same time, choose otherwise cheap material perhaps uses thinner lining lining.

Before furnace repair if discover conglutinate of existence of water-cooling furnace wall () of furnace hanging iron, must be demolished first or protect water-cooling a place with a draught, keep clear of next bur. If furnace wall has slight conglutinate only, use rope ladder to enter the chamber of a stove or furnace from mouth of feed in raw material, beat in bur upper part, prize divides conglutinate, prevent bur to fall person and scathing water-cooling a place with a draught. If conglutinate is serious, light a pipe with oxygen commonly bur of cleared furnace wall. When use oxygen lights tubal cut bur, should the cooling water outside open water-cooling wall, prevent oxygen to light wall of tubal kiln furnace.

After bur of cleared the chamber of a stove or furnace must wall of microscope water-cooling furnace, repair the attaint part of water-cooling furnace wall with arc welding, and level off of burnish of furnace wall interior. Of lining of crock of forehearth of water-cooling furnace furnace repair clear method and constant lining cupola are identical.

In lining construction process, must notice to protect water-cooling a place with a draught, prevent furnace repair material strictly to fall a place with a draught of water-cooling breaking an injury or furnace repair appliance injure blast tuyere.

Crucible is pounded dozen of makings, pouring the real character of service of makings and construction quality are concerned, pound dozen of makings, pouring makings construction must use corresponding pattern, and chase a fill fireproof material, chase a layer to pound dozen, shake is pounded, the close fact that improves data as far as possible is spent and uniformity.

In crucible lining construction, must special attention the quality of fireproof material build near mouth of iron of crucible taphole, taphole, incomplete. Taphole near mouth of iron of medium, taphole, incomplete, involve a few kinds of different and fireproof material commonly, there is more complex mutual coupling to concern between all sorts of lining material, a bit neglect leaves accident snake in the grass possibly to crucible lining.

At present advanced and fireproof material all has taller thermal conductivity, because this taphole chamfer and taphole chamfer should not be all,use build of advanced and fireproof material. If taphole chamfer and taphole chamfer use advanced and fireproof data entirely, criterion the Wen Jiang when iron fluid, slag passes taphole chamfer condenses more greatly, easily. Chamfer of taphole chamfer taphole spreads ground floor to have effect of adiabatic heat preservation with common firebrick commonly, with pound dozen of makings or surface of build of advanced and fireproof mud. The wall blocking broken bits in taphole chamfer uses silica brick build commonly. The successive taphole chamfer of water-cooling furnace shoulds not be too long, otherwise slag is easy amid condenses cause cuttings pick-up not free.

Before drying of chamfer of the water-cooling furnace lining after build or heavying repair, taphole, taphole chamfer, the natural airing that should pass period of time or low temperature are slow stoving, otherwise lining surface contains easy occurrence flaw, affect lining life.

Small the lining after repairing is roast and OK incorporate with normal ignition undertake. If lining passes the word that heavy repair and does not pass special drying, cause fusion accident or trouble extremely easily.

The stoving agglomeration of chamfer of water-cooling furnace lining, taphole, taphole chamfer should use what material asks to warm up according to place, curve of heat preservation craft undertakes. The advanced and fireproof data that uses inside the chamber of a stove or furnace, general need undertakes 200~300 ℃ complete drying after build, undertake the 1200 ℃ , agglomeration that is not less than 8 hours.

After the chamber of a stove or furnace is repaired, also need to undertake 200~300 ℃ complete drying, undertake the 1200 ℃ , agglomeration that is more than 30 minutes.