Carborundum combines nitrogen to change silicon technology

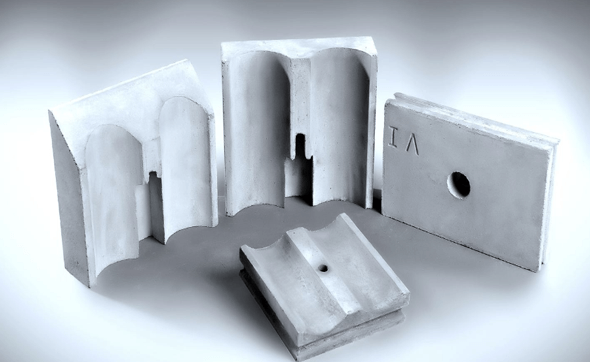

Carborundum combines nitrogen to change silicon is a kind of special type advanced and fireproof material, it is the 4th acting product of fireproof material, have relatively exceedingly good structure. The new-style firebrick that makes by this material has high temperature strength tall, heat conduction performance is good, it is good to fight function of oxidation, heatproof shake and anti-corrosive, it is good to fight sex of high temperature creep wait for a characteristic. Current, the exceeds large puddling blast furnace waist with high content of the electrobath lateral that this kind of brick basically applies at factory of modern large aluminium, technology, high-grade kiln is provided.

The SiC of will thick, medium, fine grained and Si pink are reasonable and tie-in, complementary with certain additive and bond, mix adequately in bell batch mixer, use next pouring shape, stoving hind loads large nitrogen to turn heat, firing in clean nitrogen atmosphere, make the Si in base substrate generates Si3N4, get be been with Si3N4 combinative the SiC composite material of the photograph.

This kind of nitrogen changes silicon to combine carborundum the application of fireproof material, reduce specific power consumption effectively, reduce goods blemish, improve product quality, the kiln that drops unit product has cost, it is a kind of relatively ideal new-style kiln provides data. The craft course that nitrogen changes silicon to combine carborundum brick is shown 3 times like the graph, specific process is as follows.

1, mix practice

It is normal to the machine that mix practice should be checked to whether run before mixing practice, clear foreign matter clean, to long unused the machine that mix practice should use flotsam Qing Dynasty to grind above all.

2, feed in raw material is ordinal

(1) often expects: 2.5 ~ 0.43, 1.43 ~ 0.5, 0.5 ~ 0 join, mix grind 5 minutes.

(2) old stuff joins quantity ≤10% .

(3) adds dextrin fluid to mix grind 5 minutes.

(After 4) joins dextrin of SiC fine pink, mix grind 5 minutes.

(5) adds water to undertake adjustment.

(6) is mixed completely grind time to be not gotten little at 15 minutes.

3, screening

Mix the pug that has drilled to had needed 5mm screen mesh before use, the makings on the sieve is collected centrally classics old stuff can be done to use after smashing, some will be mixed in the makings on the sieve sundry eliminate.

4, shape

Shape use 630T attrition to control bricky machine, the case such as dimension of condition of fine installation movement, model and peen level off must be examined before shaping, peen must not have electric welding broken bits, platform scale adjusts the accurate, examination that decides quality of pattern plate of very odd heavy; to check and accept the job to press a regulation to carry out by library of manufacturing division pattern plate, dimension should be examined before the model is used, spend a bit, grain should prevent to slant when ≥2.6g/cm3; of adobe bulk density says to expect analyse, pug is mixed in metage when spillage; pressurization is not being gotten when makings, use first light hind carry slow again the operation method of hammer, make sure edge horn is orderly, prevent a layer to crack the generation that waits for reject.

Increase basis of semi-manufactured goods standard appropriately, the exterior of the adobe that has squelched should the semi-manufactured goods standard according to of all kinds goods, chase piece undertake checking, eligible adobe Fang Kejin enters next line working procedure, adobe wants put down gently to be on cotton list, the gap of 3-5cm leaves between adobe.

5, dry

Adobe has nature inside dry room dry, here brick of the basis in the process reach climate situation, should flip through and expose underside going up. Between dry base substrate removed 3-5cm, dry moisture is not more than the adobe remains after 0.1% , natural and dry temperature is between 20-30 ℃ , dry time should have particular strength, figuration to be a principle with adobe. The adobe after nature is dry sends channel desiccator to undertake dry, the temperature that enter a hole is less than 60 ℃ .

6, firing

Hot project adjusts operation requirement

300 ℃ of ① build furnace lid, 500 ℃ blow steam, 600 ℃ vacuumize fills nitrogen, vacuumize makes the 2nd times fill nitrogen after half hours, next nitrogen platoon dextrin comes 750 ℃ , top pressure, pressure is 0.03Mpa, begin to exchange exhaust valve, 30 minutes are exchanged, assure the uniformity that the air current inside furnace moves.

② makes sure furnace pressure is in + 0.01 ~ + between 0.045Mpa.

The electric current when ③ stops furnace falls for 0, stop to heat, undertake nitrogen is blown cold, drop in temperature to pass discharge to 1000 ℃ , exhaust valve closes completely, condole furnace lid, wear air-blower, blow to 600 ℃ to be able to open furnace door.

7, choose giving pit

Choose operation wants serious and meticulous chase an examination, build a rule, finished product, reject should pile up in appoint a place, should plant by the brick to reject brick do analysis of good blemish responsibility, achieve exact record.

Pouring shape the main raw material of Si3N4-SiC goods is industrial pink of green carborundum, silicon. Use burden of scale of thick, medium, fine multistage, and fundamental raw material high pure green carborundum is ground via metallic silicon air current grind to 1200 eye above.

The choice of SiC particle shape is one of postulate that assure its goods high density and high strenth, the SiC particle shape that normally city makes work is more acicular, piece shape, shape in the process effect of easy generation arch bridge, shape density is not high, want to have grain plastic to SiC so. Plastic uses mill means to undertake, make grain adjacent etc indigestion form, have chemical processing, bath next, eliminate impurity.

industry silicon piece passes gnathic type broken, broken to roller, again by grind wear the size that needs to place. Count day with leach bubble next, make the metallic silicon in silicon pink changes content and water to react adequately, eliminate bleb, next stoving.

Mixture suppress becomes powdery material: Will thick, medium, fine SiC is arenaceous move with Si pink raw material put in basis of the; on platform recipe, metage SiC is arenaceous enter efficient batch mixer with Si pink; inside, open is efficient batch mixer; joins water; equably through mensurable water meter beforehand metage is good the additive that adds water dilute and temporarily bond, mix agitate adequately 15 ~ 20min, after sift out, put makings storehouse to undertake covering tightly expecting storing 24h above.

Nitrogen changes the base substrate in the process not to contract basically, accordingly the density of goods depends on the density of base substrate, the grain composition of preform is having very big effect to the density of base substrate. The density of goods is affecting product directly again firing the grain that reachs finished product turns performance.

Because SiC is material of sex of a kind of barren, precipitate easily into oar hind, pouring when appear rate suction a thick liquid is rapid, green compact intensity is low, because this should choose proper additive, make expect the oar is had good suspension, fluidity, proper touch denaturation and water content, to pouring shaping is very important. The metal is added in reaction raw material silicon and the raw material that contain carbon, collosol of silicon of class of the rice that use offer regards microtherm as binder. Should introduce a quantity to be 0.5% ~ 2.0% when, makings oar has good suspension, touch denaturation not apparent, rate suction a thick liquid is slower, pouring makings density is high, product quality is higher.

New-style nitrogen influences preparation silica brick of silicon union carbonization basically adopts the following measure.

(1) uses burden of scale of thick, medium, fine multistage, fundamental raw material high pure green carborundum is ground via metallic silicon air current grind to 1200 eye above.

(2) adds a metal in reaction raw material silicon and the raw material that contain carbon, pass reaction former a synthesis is tall carborundum of class of active accept rice, dropped firing temperature, increased strength.

(3) preform is used pouring shape craft, collosol of silicon of class of the rice that use offer regards microtherm as binder, be united in wedlock in order to realize anhydrous mud, thing of goods low frit is little, assured high temperature intensity.

Of afore-mentioned technology measure carry out producible nitrogen changes a new-style high strenth of —— of new-style and fireproof material that can replace entrance product silica brick of silicon union carbonization, this brick has apparent pore to lead low, intensity tall, have fight erode ability intensity of strong, high temperature is big, chemical good, use temperature mixes stability high wearability is strong wait for superior performance, longer than common firebrick service life, can apply extensively at the industry such as metallurgy, coloured, chemical industry, pottery and porcelain, have better society and economic benefits.