Fused Cast α-β Alumina Block (RH-M)

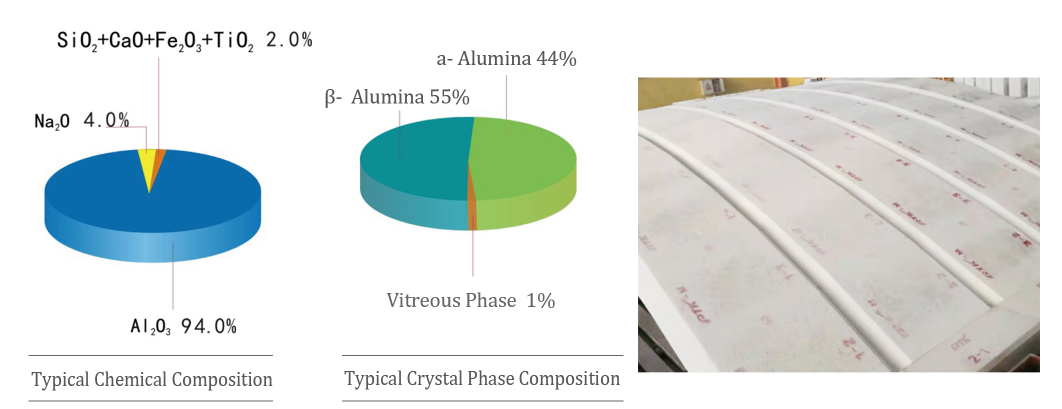

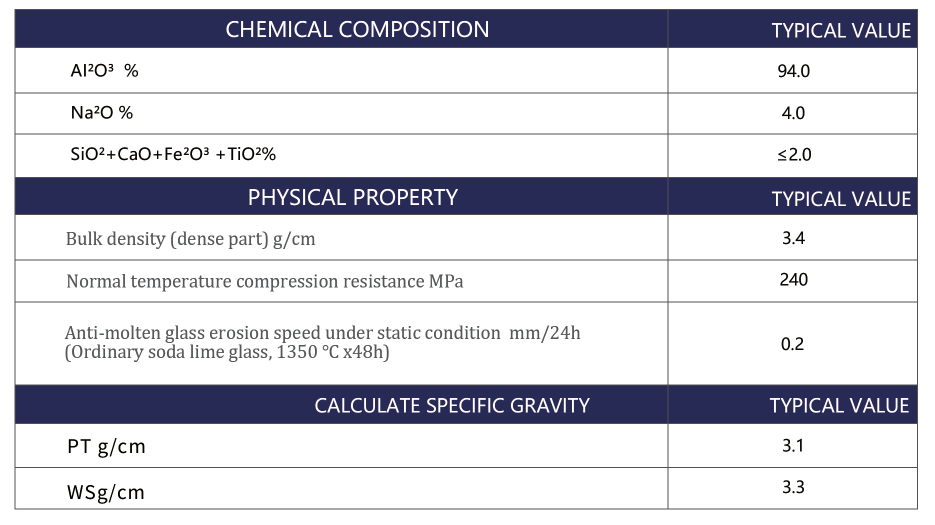

RH-M is composed of about 50% each of α-alumina and β-alumina , and the interlocking of the two crystals forms a very dense structure with excellent resistance to strong alkalis.

Its resistance to erosion of molten glass is comparable to that of AZS in the temperature range below 1350℃. Since it contains almost no impurities such as Fe203 and Ti02, the matrix glass phase is very small, and it has the excellent property of not contaminating the molten glass by minimizing the occurrence of foreign matter such as bubbles when in contact with the molten glass.

Therefore, it is the most suitable for working pool wall, pavement, material channel and channel of high-grade glass furnace.

The above values are the typical physical and chemical indicator of the block material, but not as a basis for guarantee.

Q:Are you a manufacturer or trading company?

A:We have surely been a reliable manufacturer since 2006.

Q: When can I get the price?

A: We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order,you can call us directly.

Q: What about the lead time for mass product?

A: The lead time is based on the quantity, about 7-12days. For graphite product, apply Dual-use items license need about 15-20 working days.

Q:How to guarantee the quality of your products?

A:1) Strict detection during production. 2) Strict sampling inspection on products before shipment and intact product packaging ensured.

Q: How can l get a sample?

A: A free test sample can be supplied before your first purchase order, you only need to pay the freight cost.

Notes: The price is only for reference, for the accurate price and shipping cost, please contact us.