The main components of acid proof brick is silica. Acid proof bricks is sintered at high temperature to form larger amount of aluminum enriched andalusite, which has very high acid corrosion resistance. As acid proof brick has tight structure, low water absorption rate, it can also resist to any concentration of alkaline corrosion at room temperature, but it can’t resist high temperature molten alkali corrosion. The content of SiO2 in acid resistant brick is above 70%. Acid proof bricks are widely used in chemical industry, the main applications are the masonry of acid groove, acid well, acid storage vault and ground where usually suffers the impaction of loaded acid.

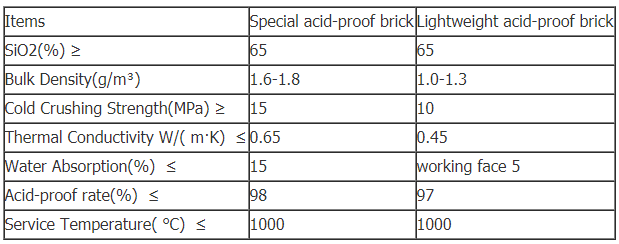

The properties of acid proof brick

Acid proof bricks mainly compromises quartz, feldspar, fireclay, when these minerals are oxidized and decomposed at high temperature, the can form corrosion resistant material, which has good acid and alkali corrosion resistance, low water absorption rate, good oxidization resistance at room temperature. Besides, acid proof bricks formed by them are not easy to be contaminated by other media. Except for hydrofluoric acid and furnace process phosphoric acid, acid proof brick has good corrosion resistance to any concentration of acids at room temperature. Acid proof porcelain bricks are usually used at places with high acid content, they are also used at sewage pipe, outdoor working grounds and so on.

The application of acid proof bricks

Acid proof bricks are widely used in petrol industry, chemical industry, metallurgy, power plant, chemical fiber, paper industry, pharmacy, fertilizer, food, galvanization factory, as well as acid tower, tank, bath, groove and other corrosion resistant projects. Acid proof porcelain bricks are also used at sewage pipe and outdoor grounds.

The paving craft of acid proof brick

1. Generally, epoxy resin, acid proof mortar, acid proof cement are used for the paving of acid proof bricks.

2. The surface of concrete should be cleaned by oxalic acid to get neutral pH.

3. The joint width is 8~10mm, the depth of the joints is the same with brick thickness to prevent leakage. After paving, the surface of acid proof porcelain bricks should be cleaned by oxalic acid to make them firmly bonded.

The application of acid proof bricks

Q:Are you a manufacturer or trading company?

A:We have surely been a reliable manufacturer since 2006.

Q: When can I get the price?

A: We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order,you can call us directly.

Q: What about the lead time for mass product?

A: The lead time is based on the quantity, about 7-12days. For graphite product, apply Dual-use items license need about 15-20 working days.

Q:How to guarantee the quality of your products?

A:1) Strict detection during production. 2) Strict sampling inspection on products before shipment and intact product packaging ensured.

Q: How can l get a sample?

A: A free test sample can be supplied before your first purchase order, you only need to pay the freight cost.

Notes: The price is only for reference, for the accurate price and shipping cost, please contact us.