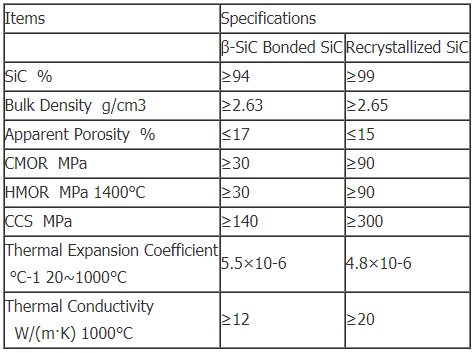

β-SiC Bonding Silicon Carbide Brick

β- SiC bonded silicon carbide brick is produced the by the combining of the original SiC particles and β- SiC generated by in-situ reaction of metal silicon powder and carbon powder in raw materials at high temperature,the bonded phase has small grain size and high activity, the oxidation resistance and resistance to water vapor oxidation erosion and mechanical strength is slightly inferior to Si3N4 bonded silicon carbide brick, but other properties are close to both.

Recrystallized Silicon Carbide Brick

Recrystallized silicon carbide brick, also known as R-SiC, is bonded by adding effective surfactant to α-SiC raw material and sintering at high temperature in protective atmosphere to make SiC evaporate and coalesce and recrystallize at the SiC particle bond. It has excellent properties such as high strength at high temperature, light weight, no slagging, good thermal conductivity, less heat storage, long life, etc. It is widely used in ceramics, petrochemical, aerospace and other fields, and is an excellent high temperature engineering material.

Silicon carbide bricks can be divided into oxide bonded (clay bonded, mullite bonded, SiO2 bonded), nitride bonded (Si3N4 bonded, Sialon bonded), self bonded (β-SiC bonded and recrystallized silicon carbide) and silicon infiltration reaction sintered silicon carbide bricks according to the bonding method.

Silicon carbide bricks are advanced refractory materials made of SiC as the main raw material, with a series of excellent properties such as high strength at normal temperature and high temperature, large thermal conductivity, small thermal expansion coefficient, good thermal shock resistance, excellent high temperature wear resistance, and strong resistance to chemical erosion, etc. Widely used in steel industry, non-ferrous metallurgy, petrochemical industry, electric power, ceramics and aerospace fields.

Q:Are you a manufacturer or trading company?

A:We have surely been a reliable manufacturer since 2006.

Q: When can I get the price?

A: We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order,you can call us directly.

Q: What about the lead time for mass product?

A: The lead time is based on the quantity, about 7-12days. For graphite product, apply Dual-use items license need about 15-20 working days.

Q:How to guarantee the quality of your products?

A:1) Strict detection during production. 2) Strict sampling inspection on products before shipment and intact product packaging ensured.

Q: How can l get a sample?

A: A free test sample can be supplied before your first purchase order, you only need to pay the freight cost.

Notes: The price is only for reference, for the accurate price and shipping cost, please contact us.