Trend of fast development of modern now Zuo , various production produces the litter that systematic software eduction comes to, breed is various, gross promotes with each passing day. So litter, to air pollution, serious with each passing day, in all normal basic necessities of life that endanger people and job, so that beautification environment, prevent the environmental pollution of natural resources of air, water and edaphic layer, ensure person installs systemic heart health, consequently, to the settlement of litter, already became various production to make an indispensable crucial move in building.

Various production produces the litter that systematic software eduction comes to, will divide by states of matter, have, solid, liquid and gas 3 categories, appellative for 3 useless. Of litter form very multifarious, be in especially the flying development of petro-chemical equipment, endanger much constituent to increase slowly, be sure to begin with measurable countermeasure solve. Settle way: Normally organic weapon standard, law suction Fu, cell biology law and tall burn processing. Various solve means to its blend in category and actor, blemish, relatively look, can tall burns processing can the much constituent that comb-out has a harm, project investment is very few, consequently, now nowadays China, outside choose burn processing is solved 3 extremely useless wide.

3 abandon the foundation that burn to machine craft standard, have burn is spent, very hot value of demand of latency time, gas and litter hair.

(1) burn is spent. Burn is spent make there is harm much constituent in litter air oxidation, deliquescent below tall , the that must exceed till wrack place is spent. Those who compare litter catch fire dot is spent get high much. Burn is spent is combustion furnace lining overall design and choose the important segment of makings.

Normally promotion burns spends much to there is a harm in litter constituent dissolve and destroy beneficial, can restrain cause vent-pipe to risk black smoke. But exorbitant when, expend expect like that, still can promote the metal in litter the number of the capacity of material and oxidation nitrogen, cause pollution. Too low much to having a harm constituent is not amounted to on dissolve thoroughly and destroy, did not amount to burn lookingly. Consequently, burn is spent have with the latency time inside the chamber of a stove or furnace closely related, if plan institute is shown. When reaching azotic oxygen compound and carbon monoxide gas burn in the graph burn is spent and burn lead (purify of harm much constituent is led) reach correlation of latency time ternary.

(2) latency time. When there is harm much constituent to burn inside the chamber of a stove or furnace in litter, harm much constituent produces air oxidation to ignite, make harm chemistry material turns into to learn material to need without harmful materialize, say to burn latency time.

The length of latency time is endangered instantly burn proper level, it is the important segment of norms of capacity of decision-making boiler setting. The appearance when litter enters furnace (if dimension of solid grain content, liquid does dimension of the liquid after pulverization and viscosity,wait) to burning latency time is endangered very big. Consequently, burn latency time is made clear by the experiment.

Burn processing solves 3 useless actor, blemish to coexist. Should contain in litter when the organic compound is less, burn need fill Zuo to aid expect like that, promotion solves 3 useless cost cost; Organic compound a long time, ignite dissolve not only have harm much constituent, the calorific quantity that comes out together can be used integratedly, decrease burn cost cost, the organic compound is being contained in inspecting litter is how many character criterion. Burn processing solves 3 useless crucial machine equipment is combustion furnace.

The sort of combustion furnace and construction

A few big sort:

Burn processing solves furnace of the combustion in 3 useless whole processes is crucial machine equipment. Chinese place has burn device introduces along with equipment of whole set of equipment for the most part. The combustion furnace that if in order to of each country of this age bound burns,handles now all ignites a method to be able to be divided into a few big sort by its.

(one) furnace platoon is ignited model combustion furnace

This kind of phyletic combustion furnace, the key is box type furnace, give earlier. Its are tectonic and simple and easy, hearth carries platoon having stove, strong point flotsam holds a nature concurrently ventilated with the effect that removes desulphurization plaster stone. The dry impetuous of flotsam and burn the radiation source that relies on flame and boiler setting. Its sort has: Fixed do not use heat platoon discharge with thematic activity furnace model 2 kinds.

(1) fixed do not use heat of furnace platoon combustion, serve real operation, intermittence to run artificially, ignite not complete, resolve practical effect difference, business gross area produces mud the quantity is inferior (make an appointment with 25~75kg/h) , reason is little use. Its construction means has: Level is fixed do not move furnace is discharged and secure askew do not move furnace platoon.

(2) thematic activity furnace discharges combustion furnace, manipulate automation technology actually, run change continuously. Because furnace platoon construction is different,divide into: Type of step move back and forth, push rod, bar moves type to wait.

(2) hearth is ignited model combustion furnace

Hearth is ignited is to be above hearth the method that blends Bian Fen to burn. Furnace of this kind of combustion has have symbolisticly: Furnace of combustion tubal form and multistage type combustion furnace. Run type combustion furnace, main use is widespread, again this narrates; Multistage type combustion furnace, because construction is trival,need heat-resisting alloy again, reason did not introduce in detail.

Furnace of combustion tubal form (appellative circumgyrate furnace) it is to use more heat model. General in order to burns various oar of silty, broken bits, fat, useless active carbon is mixed the litter such as wine cypress, also can solve oil of plastic, vulcanized rubber, vegetable an equipment organic compound such as Qing Dynasty of sedimentary, drop content of high polymer material waste.

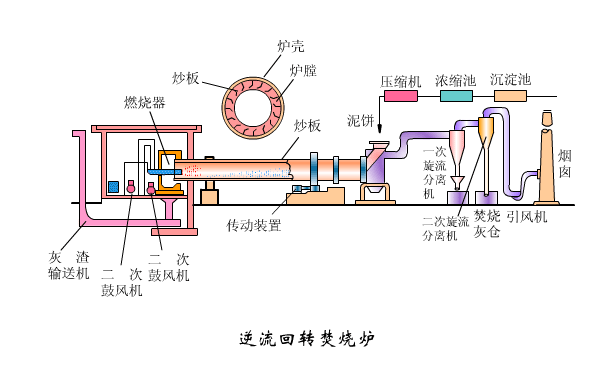

Answer the construction of converter, if plan institute is shown. It is a vertical cylindrical, with rotate dry impetuous, earth up kiln photograph to agree, by machine of end of kitchen head, furnace, combustion, gripper shoe construction and transmission system organization are formed.

The key that shaft is circumgyrate furnace one part, cylindrical li of line is fireproof insulation material liner, set inside the canister copy board or replace with liner protruding brick, shaft with 0.3? 1.5r/min is rotational.

Because manufacturing technological process is different,answer converter type of cent direct current and refluent type.

(3) interior space is ignited model combustion furnace

It is furnace platoon is ignited no matter, Zuo is hearth is ignited, flotsam all the time with conglomeration or enrage lay a finger on coming back small pieces with heat. Conduct speed because of exterior limited company, heat inferior, accordingly be forced to do adds Zuo latency time, because this is brought about,solve working ability low, burn do not wait for a chain of defect thoroughly.

Accordingly, shed voice to change crucial technology to flotsam burn on processing, because this develops a tendency interior space fires stove of circular fluid-bed combustion, furnace of combustion of appellative loop fluid-bed.

Add: Do the liner construction of furnace of circular fluid-bed combustion and fluid-bed of common loop of fireproof insulation material burn of furnace burn is spent 750? 870 ℃ , because of the raw material inside furnace (plasmid carrier and flotsam) show burn shape fluidity, regulation of reason liner material is high temperature resistant the fireproof insulation material of wear-resisting caustic. This furnace is chosen high temperature resistant wear-resisting caustic mixes clay to irrigate build in all thick 250mm. The layer uses 150mm in light qualitative concrete is high temperature resistant mix clay to make thermal insulation board, surface layer (working middle-level) irrigate build aluminous alumina of 100mm thick ammonium sulphate to mix clay, aluminous cement grog: Mud of low calcic aluminous acerbity brine: Chloridize aluminium fine pink: =100:2 of phosphoric acid aluminous aqueous solution.5:2.5:20-24(Wt) . Or with brick of heat preservation of light qualitative concrete and brick of one Ji tall aluminium (wall of LZ-65) build by laying bricks or stones.

Incinerator work environment and real operation are bit more crucial

Litter is varied, appearance is varied

The litter that petro-chemical factory solves is various, not be simplification appearance, but no matter litter is solid state hard disk, liquid or steam condition, burn from its essence will tell is to fire difficult problem completely. Consequently, when stipulating combustion furnace is in the job, common problem gives out:

(1) the combustion furnace suiting to litter ability, the combustion furnace suiting to litter ability is wider taller, if answer furnace of combustion of fluid-bed of converter, loop,burn to litter the gender is very big. But also not be in that way, capital of will all litter burns inside furnace of combustion of devoted and same table, be sure to all previous is clear via the experiment, patchy gather, the harm everything is operated actually normally.

(2) the operating period of combustion furnace, the operating period of combustion furnace depends on the service life of liner for the most part. Liner build by laying bricks or stones is over forge hind is not OK immediately capital throws production to make, wait when announcing to run, its carry lukewarm real operation, with 20 ℃ / H rate is carried lukewarm, to 650 ℃ adiabatic heat preservation 12 hour. Reoccupy 20 ℃ / is H carried lukewarm to 800? When 1000 ℃ run to spend, can feed in raw material, carry out experience to be in benignantly greatly to adding burner service life.

(3) of feed in raw material and working temperature operate, amount to inside furnace must when is spent, is quantity of feed in raw material general 1/3? 1/4, the raw material that capital throws should distributing jointly igniting bedside, prohibit deposit together. Exorbitant or working temperature is too low all can bring about environment to pollute. The vent-pipe after litter burns should accord with standard of environmental sanitation environmental protection. Operate good job temperature, be sure to operate the flame accident that Zuo aids burner is the 2/3 inside furnace following.

(4) the security that handles a staff member actually alertly, the raw material that burn all contains harmful much constituent, person is safe not lay a finger on, prevent boiler setting to spend burn, avoid burner run risk a state, maintain small air pressure is real inside furnace operation.

(5) inside combustion furnace, outside often keep clear of, maintain clean neat, cannot have all round burner flammability, combustible explode easily thing Chu Fang.

(6) berth car, stop feed in raw material first, combustion machine stops after, prevent the stink that causes inside firebox and vent-pipe to risk black smoke to wait to was not burned smooth and discharge. total investment subsequently mouth, passageway is put out completely, prevent temperature to control pelter, adverse drive to moment.