Firebrick makes a process shape mediumly, it is to point to have the aid of of fireproof raw material to machine preform the process of the base substrate of set dimension and appearance at outside force and model. However, the take its natural course that develops newlier is pouring the construction of makings basically does not need outside force.

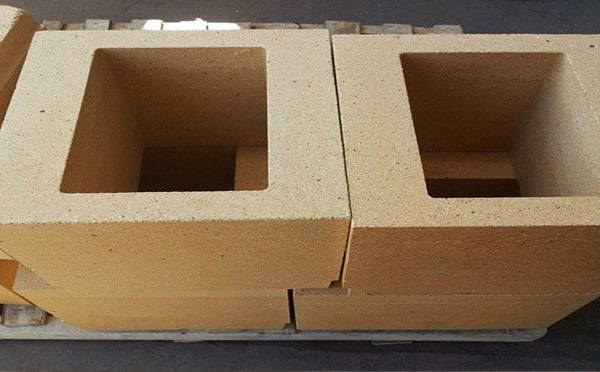

Of firebrick shape, it is to satisfy the use requirement of goods above all, goods of the requirement when firebrick build by laying bricks or stones is built has proper form, exact size and enough strength. Next, shaping also is the significant step that raises goods manage to turn performance, can improve the constituent structure of goods through shaping.

The method that firebrick shapes is very much, shape traditionally how many minutes when the method presses preform water content to be:

(1) works a way partly: Its preform water divides 5 % left and right sides, apply to clinker content to differ (% of 50 % —100) preform;

(2) but model law: Its preform water divides 15 % left and right sides, apply to make the product with large or complex form;

(3) notes oar way: Its preform water divides 40 % left and right sides, apply to the of all kinds and fireproof material that produces hollow Bao Bi.

Of firebrick shape the method is very much, shape commonly usedly method organic pressure shape law, vibration shapes law, extrusion law, pound dozen shape, etc static pressure shape, founding shapes, note an oar to shape etc. Why is the choice planted shape the method is main requirement of craft of etc of the appearance according to pug property, base substrate, dimension. Outside using machine pressing to shape except majority firebrick, vibration shapes to be used at shaping commonly big abnormity base substrate, extrusion uses at be in charge of shape base substrate commonly shape, note an oar to shape to be used at the base substrate with hollow thin wall to shape commonly. Etc static control the production that shapes to basically be used at high-powered fireproof data at present. Of course, shape methodological choice still gets the limitation of manufacturer equipment condition, consequently certain firebrick cannot be used relatively of beautiful shape method. Below this kind of circumstance, below the premise that the enterprise should ask in contented firebrick technology, the option is other relatively appropriate shape method. Use no matter why to plant method, the base substrate after shaping should satisfy following requirement:

(1) appearance, dimension and precision accord with design requirement;

(2) structure is even, compact, the surface and interior are flawless;

(3) has enough mechanical strength;

(4) accords with expectant physical performance to ask. The treatment process of firebrick base substrate is namely shape, its are main the method has: Machine pressing shapes, etc static pressure shape, founding shapes, vibration shapes, pound dozen shape, extrusion, hot pressing shapes etc.

Firebrick manufactures technology, smash - mix refine - shape - firing - pack - deliver goods.

By aluminous alumina or other oxide content taller raw material classics shapes to be become with to calcine. Thermal shock stability is tall, fireproof degree in 1770 ℃ above. The sex that fight broken bits is better. The liner that firebrick basically uses at build by laying bricks or stones to build furnace of circumgyrate of forge of steel-making electric stove, glass, cement to wait. When content of the Al2O3 in the brick exceeds 71.8% , the Al2O3 of over forms corundum crystal below high temperature, make appearance of brilliant of 2 high temperature at the same time, in all frit temperature rises to 1840 ℃ by the 1595 ℃ of brick of low Al2O3 content.

One, raw material

1, use fancy aluminous aluminous grog to do advocate makings.

2, Xie Lashi fine pink 325 eye, its composition basically is Al2O3≥18% , Al2O3≤0.5% .

3, combinative clay (Shanxi is soft qualitative clay 190 eye) its bases is Al2O3≥34% , Al2O3≤1.0%

4, water

2, powdery makings preparation:

1, because tall aluminium is aluminous time of outdoor the other side is longer, want before put into production sundry and outside interfuse impurity, will cleared.

2, ripe aluminous makings, take broken system broken. With sift out of 3.0mm screen mesh.

Granuality requirement: ≥3mm 3-1mm ≤0.088mm 4-8% ≥60% ≤10%

3, fine pink of wear of engine of Ramon of inclined classics of the makings on partial sieve.

Granuality requirement: ≤0.088mm ≥95%

4, one workshop parts 2 product line strictly, produce tall aluminous brick with. Cast antenatal to rest clinker, fine pink to expect the storehouse reserves respectively.

5, clay of Xie Lashi, Shanxi says to weigh respectively, in loading a bag, reserve.

3, pug preparation

1, burden: Clinker, fine pink, clay, Xie Lashi, water (adscititious)

2, mix refine: Order of feed in raw material, static mix 15 minutes, there must not be slimy group and drier in makings. (moisture is OK according to shaping circumstance control is adjusted)

3, shape:

4, the model puts foot: Do not separate position, long, wide 0.5% , thick 0%

Embryo of brick of close 2.95g/cm3 of body of firebrick brick embryo is stomatic: Standard of size of 22~23% firebrick semi-manufactured goods: When ≤100mm of bricky embryo dimension, its error is in ±1mm: Be in when embryo of brick of tall aluminous brick 100~200mm, its error limit is in ±1.5mm: When the dimension ≥1.5mm of firebrick: When the dimension ≥200mm of firebrick, its error is in ±2mm.