Case study:

(1) build by laying bricks or stones builds a project to contract square responsibility heart is short of break. This company overhauls height to take seriously to spending craft second year originally, ahead of schedule two months organize invite public bidding, build by laying bricks or stones of famous kiln furnace builds a company to come round to bid inside much home industry, examine through strict aptitude, the programme of construction and safeguard measure are discussed, the link such as doubt evaluates actor integratedly to single out win the bid contract square. Because the overhaul is centered during the Spring Festival, contract a many building site in succession start working overhaul, the member that cause construction person is in short supply, contract square privately gives tripartite project subcontract, and govern on somebody's behalf in order to wrap the phenomenon is serious.

(2) build by laying bricks or stones builds weakness of staff technology strength. Because contract a many building site at the same time construction, personnel is dispersive, project technology personnel is in short supply, temporarily the build by laying bricks or stones with sub due lack builds technical ability. Because bricklaying difficulty is locking up buccal position, only technical personnel is gone to by arrangement on bricklaying machine, ignored demand of the technology end the shop.

(3) technical essentials is not fulfilled reach the designated position. Quality superintendent discovers, bottom annulus appears for many times to photograph adjacent firebrick successive 3 “ unplug stage ” phenomenon. Disobeyed “ firebrick bottom and cylindrical shell badly 100% contacts, annulus to firebrick between two of 100% contacts ” 100% requirements, instruct pair of “ to unplug stage ” is in tone brick to weigh build by laying bricks or stones.

Solution:

(1) government of aggrandizement construction army. On the choice of construction team, height takes configuration of project technology personnel and engineering outstanding achievement seriously, the build by laying bricks or stones in collaboration of first consideration all previous builds the team with superior quality, of the programme of construction of whole journey supervisory engineering fulfil. Forbidden project subcontract.

(2) perfect build by laying bricks or stones builds a technology to groom. Construction just should begin build by laying bricks or stones to build a technology to groom in the round, perfect build by laying bricks or stones builds technical tell sb one's real intentions, key of key technology personnel grooms,

(3) strengthen process quality management. This second build by laying bricks or stones builds a course in, this company arranged technical superintendent, but personnel amount is insufficient, do not have without whole journey seam supervise, restricted supervisory quality. In the meantime, need change sense, degenerative quantity is supervised check and accept for quality, accuse quality canal col reach.

(4) firm establish quality consummate consciousness. Reasonable arrangement project plans, setting of time limit for a project should ensure project quality strictly.

(5) close firm board is added reach the designated position. Because go up,transfer belt firebrick coefficient of expansion is small, build by laying bricks or stones builds an end, after coping, bottom increases close firm board, rotary kiln turns slow 90° , answer to check coping, bottom brick to seam soft spot again, intensify firm board.

Limekiln firebrick (perpendicular kiln) choice principle is to should be fought above all alkalescent strong, the firebrick with compact good strength, fight fall off the firebrick with strong sex. A lot of limekiln firebrick users react bricky phenomenon happens again and again.

Here, I say two aspects. One is firebrick choice, a build by laying bricks or stones that is limekiln furnace is built. The ash of firebrick is seamed is the weak point after boiler setting build by laying bricks or stones has been built, furnace of build by laying bricks or stones when, the aperture that the hole that firebrick build by laying bricks or stones builds leads big, bricklaying greatly reaction of carbon of alkali metal oxide, analyse created reaction place. Air current of the brim in the operation crosses minute of development to be able to make temperature of hot area of boiler setting work exorbitant, created a condition for temperature action, make bricky build by laying bricks or stones flakes prematurely.

The Mo Laishi composition in alkali metal oxide and firebrick generated a series of reactant to also cause bulk to expand, origin of these alkali metal oxide have two kinds, one kind is to come from Yu Ran to expect, one kind comes from with fireproof material itself. The SiO2 reaction in these alkali metal oxide and firebrick is formed low melt the compound of temperature, form furnace tumour, cause the damage of lining. The Molaishi in alkali metal oxide and firebrick 3 aluminium 2 silica (3Al2O3.2SiO2) reaction forms potassium nepheline (K2O.Al2O3.2SiO2) leucite (K2O.Al2O3.4SiO2) , accompany the volume that has 30%~50% to expand at the same time, and the melt temperature of potassium nepheline is controlled in 1100 Celsius, what affect fireproof data badly is fireproof degree. Consequence is to cause lining to flake. Wei Ran belt is hit pouring makings, make sure temperature causes unified temperature in bottom and upside, raise temperature of the vapour inside heat pipe. Study via fireproof material the branch studies: The destruction of alkali metal the mainest reason that action is bricky line attaint, its occupy the proportion that destroys entirely to amount to 40% the left and right sides. Of fireproof material raw material mix except iron except alkaline very important, compare except iron simple, but it is difficult to be compared except alkaline impurity K2O/NA2O/R2O, r2O is the abbreviation of one price oxide. The assurance of impurity of oxide of this alkali metal must rely on high grade raw material.

Of thermal stress destroy. Temperature of firebrick working face is close to temperature of brim coal air current, working surface temperature is adjacent 1400, and temperature of firebrick other one aspect of the matter is low, the temperature difference of two end is in 400 degrees of above, such bricks produce very great thermal stress inside line, this kind of thermal stress is as high as 40MPa, must choose the fireproof stuff with expensive coefficient of thermal conductivity so. Firebrick heats up what the thermal stress that carries generation forms to expand to fall to move like Leng Duan in high temperature, bring about boiler setting to form annular break easily. And the existence that because have steel casing and insulation material,the requirement of firebrick lining heats up another end at the same time namely is gotten cold, must choose the firebrick with tall coefficient of thermal conductivity so.

Erode mechanically machinery erodes with wearing away is flow of iron of the broken bits inside the crucible that point to to crucible wall erode, the gas band that combustion belt forms is worn when powder moves up, be opposite of boiler setting lining wear away and load the charging inside furnace to be in from roof drop be opposite in the process of lining wear away

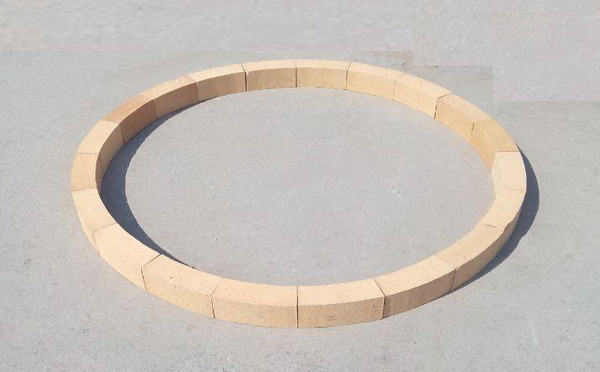

The expression that rotary kiln uses firebrick heating surface the method is to examine handy and quickly whether wedge firebrick builds what use firebrick with different kiln diameter to identify by right way build by laying bricks or stones mark method.

Main mark method uses method of “ groove ” , can use according to need colored express to be noted as additional number (whether to need to colour specification answers by agreement of both sides of supply and demand) .

One: ? Block noise of expose sb's misdeeds or crimes?

Identify to facilitate, the appearance of every kinds of groove should differ, body of thorough brick. All notch periphery should show arc. Next graphs 1 gave out appearance of 3 kinds of groove, but optional among them a kind. The dimension of groove does not make a provision.

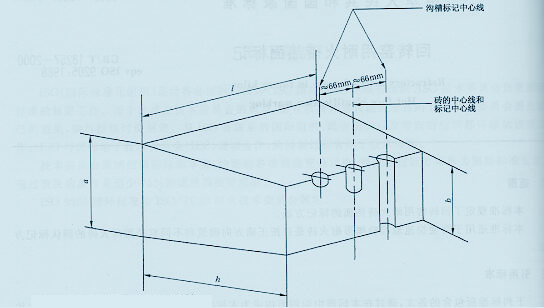

2: Mark position

Groove should be located in firebrick line of hot side center what go up or be apart from this center line to make an appointment with 66mm is linear on, if pursue,1 is shown.

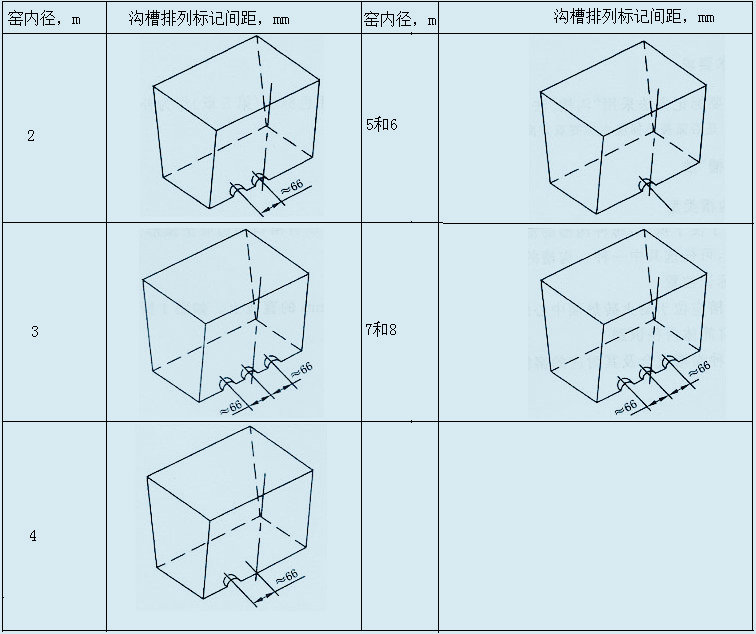

3: Internal diameter of kiln cylindrical shell identifies

5 in groove combination and internal diameter of its corresponding kiln cylindrical shell see a picture

4: Color labels

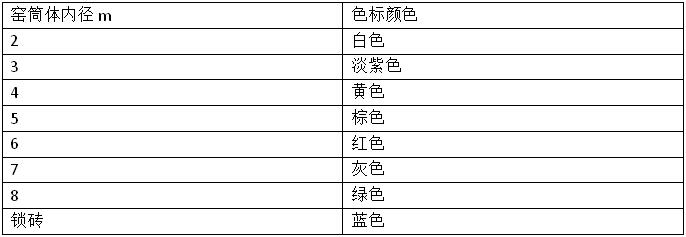

Using color mark method is the complement of pair of groove laws. Color labels a series of color that make clear internal diameter of different kiln cylindrical shell label. These chromatic mark should be in before shipment on hot side of Tu Zaizhuan, the brightness of color and chroma should enough identifies clearly all sorts of firebrick, place of all sorts of internal diameter of kiln cylindrical shell see next tables with color.