Do not touch aluminium pouring expecting is with fancy tall aluminous alumina aggregate is given priority to, add α-Al2O3 small pink, palm corundum fine pink and a kind of additive, with aluminium acid calcic cement is bond, of preparation fireproof and pouring makings, detect respectively the index after its normal temperature and high temperature are burned. The result makes clear, this are pouring makings have strength it is good that the tall, waterlogging that fight aluminium appears a gender wait for an advantage.

At present place of domestic frit aluminous furnace uses fireproof material to all react at aluminous fluid, many aluminous ash is made in fusion process, created the waste of aluminous industry, and service life is brief, aluminous fluid returns meeting and fireproof material to produce reaction, in make foreign matter and entering aluminous fluid, pollute the purity of aluminous water, affected the performance of aluminium alloy directly. And do not stick aluminium pouring material is not only do not produce aluminous ash, can save aluminous ingot, do not drop to the middle of aluminous water foreign matter, the function of clean aluminium fluid, and service life is extremely long.

Do not stick aluminium pouring makings with high pure the low cement content that Shi Weiji of line of Molaishi, andalusite, silicon expects, new-style material that exceeds small pink union. Because choose high pure raw material, exceed small pink union, this series material has stability of high volume density, high strenth, good thermal shock, through adding right amount “ not wetting agent ” (be like high pure salt of oxidation chromium, compound barium, compound zinc salt) , can reduce substantially aluminium and alloy, slaggy the wetability to fireproof material, the corrosion resistance of the aluminous fluid that raised fireproof material to wait for chemical composition to containing salinity, flux, fight erode gender, do not touch aluminium and broken bits function, prevented aluminium and alloy, slaggy infiltration namely fireproof material, prolong lining life. Special apply to fused furnace, quiet place furnace, launder, aluminium to wrap liner.

Experimental process:

Raw material choice

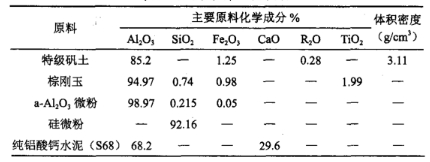

As a result of SiO2The material with higher content produces reaction easily with aluminium and aluminium alloy, fireproof to this kind ability often is eroded serious, because this chose Al2O3A batch of material with higher content, in order to rise pouring the waterlogging fighting aluminium of makings shows ability. The test is main raw material: Cement of small pink of corundum of high grade and fancy alumina, palm, α-Al2O3, silicon small pink, aluminous acerbity calcium, additive.

Express manage of 1 main raw material to change target

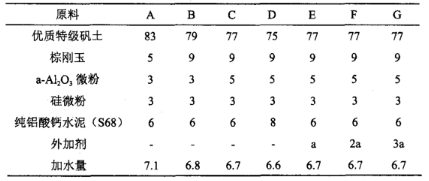

For textual research different constituent is opposite fireproof and pouring the effect that arrange changes target, had many test, listed only here it is certain to be had below a few groups of representative recipes undertake demonstrative, matrix of the aggregate in every groups of recipes deserves to compare for 70:3.

Watch 2 fireproof and pouring makings experiment deserves to compare

Sample preparation and manage change target

Undertake strict metage according to the recipe, dry inside mixer mix even hind, join right amount cleanness water agitate is sufficient, vibration shapes make 40mm×40mm×160mm appearance, the drawing of patterns after natural conserve 24h, via drying of 110 ℃ ×24h hind, have heat treatment in 1000 ℃ respectively, observe the function index condition of each recipes.

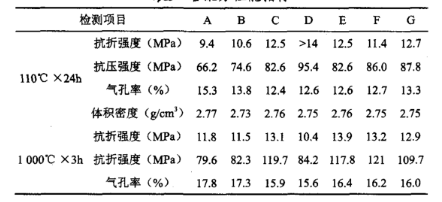

Experiment index of each recipe function detects as follows:

Express index of function of 3 each recipes

Experimental result is analysed

Cement and intensity change concern

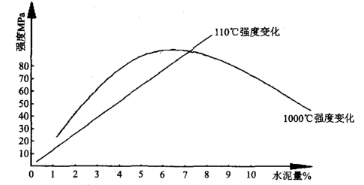

C, D basically compares cement two groups to measure the effect of index of how many pairs of intensity. Make clear through much test data, the strength of the sample below normal temperature is main by aluminium acid calcic cement is offerred, cement joins a quantity to jump over many intensity to jump over tall; but after be being handled through high temperature, aluminous acerbity calcic cement adds a capacity much, the intensity after burning drops fierce; and add a capacity less, the intensity after burning promotes apparently. General cement joins a quantity to be in 7% the left and right sides is critical point, little it is commonly at the after burning intensity of 7% increase, prep above 7% when the intensity after burning begins to drop. Consider construction factor integratedly, cement quantity joins too small conference to affect intensity of time of drawing of patterns, drawing of patterns, normal temperature intensity to wait, aluminium acid calcic cement joins a quantity finally to be certainly 6% .

The affiliation of cement estimates basically as contented as intensity relation figure 1 is shown.

Graph 1 cement adds quantity and intensity concern plan

Corundum of aluminous small pink, palm and data strength change concern

α-Al of makings of the matrix in sample2O3Small pink, palm corundum pink on one hand because fine, it is 325 eye above commonly, very good fill effect can have after joining, to intensity index by greater help; on the other hand, α-Al2O3The active meeting of small pink makes its fall to produce to hydrate and produce reaction to generate Molaishi with the SiO2 in the system in inferior temperature, with aluminium acid calcic cement joint action increases the strength after the high temperature of sample is handled, accordingly, we chose α-Al2O3 small pink and palm corundum pink to add a capacity opposite more, intensity is amiable the index such as aperture all before excel the C recipe of a few groups of recipes, undertake fighting erodent an experiment on the foundation of this recipe, in order to define first-rate test program.

Of material fight erode research

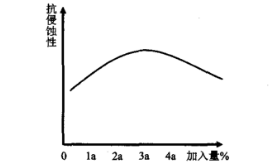

What we choose is a kind of compound additive, the destination that adds additive is to make its precede over other the aluminous water in fireproof material stoma produces composition and infiltrate through chemical reaction, make a kind of stabler material, form a compact block secondary floor, what stopped aluminous water effectively thereby is farther erode, have the effect that shows to impervious, on the foundation of C group prescription, add compound additive respectively, join a quantity to be A, 2a, 3a respectively. Respectively a few groups of sample 70mm×70mm×70mm is made after sufficient agitate, the test block of ΦΦ30mm×40mm is for nothing inside, 24h of conserve of the nature after drawing of patterns, repass drying of 10 ℃ ×2h, after loading broken bits appearance to have heat treatment of 1000 ℃ ×3h, compare tangent plane to erode a circumstance respectively.

From tangent plane discovery, tangent plane of group of A, B, C erodes a layer to submit form of disperse the internal heat with sudorifics, erode opposite more, a group particularly serious; And F group appears more bright and clean, erode a layer to show more apparent linear, because although,aluminous water and additive reaction make the case of group of;E of be caused by of a compact layer, G group,be group of excel A, B, C, but all want difference relatively quite with F group, accordingly, the affiliation of this kind of additive is measured is not more better, when joining quantity 2a, additive and aluminous water reaction are sufficient, material has wetability of admirable the water that fight aluminium, fight aggressivity best.

Additive is joined quantity and fight aggressivity concern attempt

Large frit aluminous furnace is special do not stick aluminium pouring expecting is special designs in the light of industry of domestic frit aluminium aluminium alloy fusion is used pouring makings. This is pouring makings can show raise frit aluminium alloy the service life of furnace, do not produce aluminous ash in aluminous fusion process, do not written guarantee corundum tumour, prevent metallic aluminous solution to produce reaction at the element in fireproof material, avoid foreign matter to enter quality of aluminium alloy of the influence in aluminium alloy thereby. Lower the adherent rate of aluminous fluid, increase the capacity that prevent ooze.

Do not touch aluminium pouring makings technology effect is in the following 3 respects have reflect apparently;

1, solve aluminium industrial the fireproof data reaction at aluminous fluid problem, the new-style data that uses proper motion development does not produce aluminous ash in process of aluminous fluid fusion, do not erode, do not written guarantee tumour. Can huge reduces the aluminous fluid loss in aluminous fusion process.

2, in pouring join in makings compound exceed fine pink to reduce pouring the porosity of makings is amiable Kong Kongjing, adhere to and permeate what prevent aluminous fluid. In aluminous fusion process, do not stick aluminium, do not hang broken bits, do not produce aluminous ash.

3, huge reduced the reaction of aluminous fluid and fireproof material, improve the quality of aluminium alloy.

Do not touch aluminium fireproof and pouring expect even if pledge in tall aluminium pouring a variety of additive are added on the foundation of makings, let pouring makings is more compact, good compact performance prevents the osmosis of aluminous fluid, the function of additive can be in pouring reflector is formed in makings, prevent aluminous fluid felt to be in pouring destroy on makings pouring the structure of makings, this function is just like in oil of layer of the Tu Yi on glass or olefin, let water cannot permeate same argument.

If you contact aluminous fluid respect to use in frit aluminous furnace,do not stick aluminium pouring the liner that when expecting, should notice to observe frit aluminous furnace, because be used on frit aluminous furnace,do not stick aluminium pouring when expecting, to its the accident of life has particular concern, meanwhile the use that we want to lengthen frit aluminous furnace is about to choose what quality stabilizes not to stick aluminium pouring makings, if its quality is flabby,the effect that if deciding, aluminous to frit furnace causes is more or less, direct is the manufacturing quality that matters to aluminous fluid, do not stick aluminium so pouring the word that the quality of makings is not extraordinary stability causes to frit aluminium furnace damaging also is quite big.

1, of lining of frit aluminous furnace mar a reason

Lining of frit aluminous furnace mars a reason basically to have 3:

The aluminous frit fluid inside 1) furnace, although temperature is not tall, but provide extremely permeate force, the stoma that the aluminous frit fluid with very tall active passes lining, microgroove slowly among infiltration lining, produce physics, chemical reaction with lining, slowly loose flake lining, cause lining crackle to increase, fall off.

The aluminous frit fluid inside 2) furnace and lining happening chemistry react, form conglutinate, time grows conglutinate grow in quantity to form tumor condition other people, cause damage to lining.

3) raw material is joined or in the process of taphole, aluminous stone or aluminous broken bits create certain level to lining bump, wear away etc, cause lining physics loss.

2, do not stick aluminium fireproof and pouring the characteristic of makings

Do not stick aluminium fireproof and pouring makings use corundum of fancy tall aluminous alumina, palm, cyanite, alumina to the scale with small pink of cement of small pink, aluminous acerbity calcium, silicon and special additive rigorous course mixes and be become. The low cement that the use requirement that is aluminous furnace of special basis frit develops is fireproof and pouring makings. Its have matter content low, high density, high strenth, Gao Kang erodes ability, Gao Kang osmotic, be not invaded by aluminous frit fluid the function characteristic of embellish. Express 1 to do not stick aluminium fireproof and pouring the function index of makings.

Watch 1 do not stick aluminium fireproof and pouring the function of makings

3, do not stick aluminium fireproof and pouring the application of makings

Do not stick aluminium fireproof and pouring expect with its are fought primely aluminium erodes ability, can use at next hearth of frit aluminous furnace, boiler setting, gather up broken bits brae, chute, aluminous water bag suffer erode serious place. After using, aluminous fluid is eroded, knot tumour phenomenon gets greatly control, defer.

Do not stick aluminium fireproof and pouring expect as frit aluminium furnace measures a body the lining material of custom-built development, in the construction of frit aluminous furnace that has applied factory of many large aluminium of domestic, aluminium alloy to process a business. Current, user report is consistent and favorable, its superior performance, lengthen frit aluminous furnace effectively to use cycle to be in 10 months above.