Light qualitative tall aluminous brick calls tall aluminium adiabatic firebrick again, it is the Al2O3 content that controls for main raw material with aluminous alumina do not be less than the products of adiabatic and fireproof data of 48% , a kind be light qualitative firebrick. Normally cent is light qualitative tall aluminous brick two kinds: One kind is what make for main raw material with natural aluminous aluminous grog is common light qualitative tall aluminous brick, another kind is what make for main raw material with electric frit or agglomeration alumina is high grade light qualitative tall aluminous brick, because of its advocate brilliant photograph is corundum, call light qualitative corundum the brick again. Common light qualitative tall aluminous brick is according to density cent: 1.2, 1, 0.8, 0.6 wait.

Light qualitative tall aluminous adiabatic firebrick is do not be less than the adiabatic light qualitative firebrick of 48% for main AL2O3 content with aluminous alumina. Its produce craft to use bubble method, also can use burn oneself out to add content way. Tall aluminous qualitative adiabatic light qualitative firebrick can be used at build by laying bricks or stones to build thermal insulation and erode without stock of melt of intense high temperature reach erode the place of action. When be being contacted with blaze directly, the temperature of watch surface contact of general tall aluminous qualitative adiabatic firebrick does not get prep above 1350 ℃ . Mo Laishi pledges adiabatic firebrick can contact blaze directly, have high temperature resistant, intensity is high, energy-saving effect is distinct wait for a characteristic. Apply to roller of the furnace that heat up solution, hot-blast stove, pottery and porcelain kiln of drawer of porcelain of path kiln, report and the liner of all sorts of resistor furnace.

Light qualitative tall aluminous adiabatic firebrick is one of adiabatic and fireproof data that compare ideal at present, have compression strength tall, coefficient of thermal conductivity function of low, heat preservation good, price is low wait for a characteristic, apply extensively already at kiln of body of kiln of channel of pottery and porcelain, roller path kiln, shuttle type kiln, wall now, material of liner of heat of all sorts of heating furnace cooking that also are used at steely industry and facilities of other hot project, heat treatment, have wide market perspective.

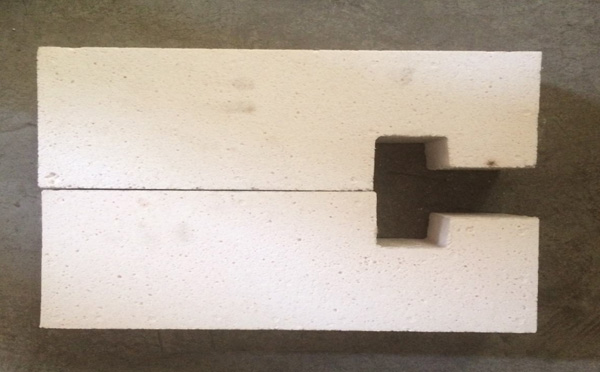

Light qualitative tall aluminous brick calls light qualitative tall aluminium adiabatic firebrick again. Alumina content is in 48% above, main the light qualitative fireproof material that constitutes jointly by Molaishi and vitreous photograph or corundum. The light qualitative tall aluminium that flourish Cheng Naicai produces is adiabatic 0.4——1.35g/cm3 of firebrick bulk density. Porosity 66%——73% , compression intensity 1——8MPa. Heatproof shake performance is better. Use tall aluminous aluminous grog to add a few clay normally, law or bubble law produce with gas after classics mill with slop form pouring, figuration, classics 1300——1500 ℃ is firing. Also can replace partial alumina grog with industrial alumina sometimes. With the liner that builds kiln furnace at build by laying bricks or stones and thermal insulation, and erode without stock of melt of intense high temperature reach erode the place of action. When be being contacted with blaze directly, temperature of watch surface contact does not get prep above 1350 ℃ .

The firebrick of boarding lump heat insolation that pledges adiabatic firebrick fastens interior to have adiabatic property for poriferous structure gently, mix with the production of bricky form product among them application is most wide, reason calls light qualitative adiabatic firebrick again. Light qualitative adiabatic firebrick presses his to material pledges or make place undertake classify and naming with raw material normally. For example, pledge with clay, silicon and the light qualitative firebrick that waits for raw material to make character calls tall aluminium respectively brick of light qualitative clay, light qualitative silica brick and light qualitative tall aluminous brick. Listed below by made the raw material that light qualitative firebrick uses and composition list the sort of light qualitative adiabatic firebrick and characteristic.

The production methods of brick of light qualitative heat preservation has commonly undermentioned a few kinds:

① becomes brick from cut of natural and poriferous light qualitative Yuan Yan directly;

② with natural or man-made is poriferous light simple stuff makes a brick for raw material;

③ joins the combustible of easy burn-up in pug, be like light ball of rice husk of sawdust, char, polystyrene; Or add sublimate substance, be like naphthalene, burn oneself out, poriferous structure is formed after volatilizing;

④ adds foaming agent in pug, be like colophony black, firing hind acquire poriferous structure;

⑤ adds carbonate, aluminium powder and hydrochloric acid in pug, reaction of chemistry of have the aid of gives off gas and form poriferous structure. Generally speaking, use ④ of ② ~ to plant the method is more.

One, light qualitative tall aluminous brick is characteristic

1, thermal shock stability is good.

2, bulk density is small, effect of heat preservation heat insolation is good.

3, high temperature capability is stable.

4, energy-saving effect is good.

2, utility of light qualitative tall aluminous brick: Basically use at build by laying bricks or stones to build thermal insulation and erode without stock of melt of intense high temperature reach erode the place of action, use temperature is in material of liner of the furnace of heating furnace cooking between 1500 ℃ of 1000 ~ and facilities of other hot project, heat treatment, if be contacted with melt content, the surface contacts temperature cannot prep above 1350 ℃ .

3, light qualitative tall aluminous brick makes a process

Light qualitative tall aluminous brick uses tall aluminous aluminous grog to be main raw material commonly, add a few clay and bond, according to certain proportional deserve to compare, via mixing refine hind uses bubble method or aeriform happening law is opposite with slop form light qualitative tall aluminous slop undertakes pouring, shape, the drawing of patterns after classics is dry is become by high temperature fire.

The important segment in pledging tall aluminous brick makes a process gently is burden and epispastic, want what good according to the design prescription controls raw material to deserve to compare above all, want to notice epispastic technology in epispastic process next, make epispastic stoma even, the use after facilitating light qualitative tall aluminous brick is made.

4, light qualitative tall aluminous brick uses a note

1, light qualitative tall aluminous brick is used as heat preservation brick commonly, not with slaggy or melt content is direct contact. High grade light qualitative tall aluminous brick can be contacted with melt content, temperature does not exceed 1350 ℃ . Specific use method of light qualitative tall aluminous brick designs requirement regulation according to the technology please.

2, intensity of press press of light qualitative tall aluminous brick is poorer, cannot get stronger pressure consequently, avoid bricky body craze.

3, when build by laying bricks or stones builds light qualitative tall aluminous brick, deserve to pledge slop is used gently.

4, when depositing, had done moistureproof and waterproof processing.

Manage of light qualitative tall aluminous brick changes target:

|

Name |

Light qualitative tall aluminium is qualitative |

||

|

|

LG-0.6 |

LG-0.8 |

LG-1.0 |

|

Bulk density (G/cm3) |

0.6 |

0.8 |

1 |

|

Intensity of normal temperature compression (MPa) ≥ |

1.96 |

2.94 |

4 |

|

The heavy change that burn a line 1300 ℃ ×12h (% ) ≤ |

1350 |

1400 |

1450 |

|

|

0.5 |

0.5 |

0.5 |

|

Coefficient of thermal conductivity is average temperature 350±25 ℃ (W/k·m) |

0.25 |

0.32 |

0.45 |

|

0.1MPa loading bate begins temperature (℃ ) ≥ |

1300 |

1350 |

1380 |

|

Al2o3(%)≥ |

50 |

52 |

52 |

|

Fe2o3(%)≤ |

1.8 |

1.6 |

1.5 |

|

Highest use temperature (℃ ) |

1300 |

1350 |

1380 |