Vitreous kiln has oxidation silicon content with high grade silica brick,

Melt index

Low and characteristic, the upside structure such as wall of the Xuan top that basically is used at vitreous kiln, parapet, condole, port and

Regenerator

Xuan.

Silica brick of tall heat conduction changed index respect to have in structure of shape of structural form appearance, brilliant, manage very big improve. The structural form appearance of silica brick of tall heat conduction, magnify to the structural form appearance of silica brick of tall heat conduction and traditional silica brick 20 times junior travel compares discovery, aperture of stoma of silica brick of tall heat conduction is more petty, distributing more even also.

Silica brick is with SiO2 content is not less than the silica of 95% to be raw material, add mineralizer and bond, via mixing refine, shape, dry, firing wait for working procedure to be made, scale can be formed after passing high temperature quartz, Fang Shiying and a few leftover quartz and vitreous photograph, when ℃ of 220-240 of Fang Shiying be heated is controlled, the heat that produces certain level expands, silica brick is the biggest expand happen between 100~300 ℃ , before 300 ℃ expand the 70%~75% that the quantity measures to always expand about. Its reason is SiO2 appears in drying-out process 117 ℃ , 163 ℃ , 180~270 ℃ with 573 ℃ 4 brilliant form changes a spot, among them between 180~270 ℃ , the volume that causes by Fang Shiying expands the biggest.

Content is the scale quartz of silica brick of tall heat conduction 70% , content is the scale quartz of traditional silica brick 60% , content compares the scale quartz of silica brick of tall heat conduction the scale quartz of traditional silica brick content is high 10% , scale quartz is structure of spearhead shape macle, very compact, be helpful for thermal conductance rise. After silica brick of tall heat conduction was raising thermal conductance, other property index and silica brick of traditional Jiao Lu are consistent. That is to say, silica brick of tall heat conduction acceded entirely the advantage of silica brick of traditional Jiao Lu, stressed the character of tall heat conduction further on this foundation.

When pug of preparation silica brick, the useless silica brick of certain amount is added normally in burden, its purpose is expanding at reducing what arise when goods is firing with stress, reduce the generation of crackle, raise n. Its join the appearance of quantity and brick and weight to concern. The different that is less than the different of 25kg brick to be able to join 20%;25kg above to weight brick can join 30%; to distinctive model silica brick can be joined 30% . Such problem should note when adding useless silica brick, those who join a quantity to be able to drop product too much is fireproof spend and mechanical intensity, increase porosity, so, useless brick joins a quantity to should not be overmuch.

Silica brick belongs to acidity and fireproof material, loading bate temperature is as high as 1640 ~ 1670 ℃ , use bulk for a long time below high temperature to compare stability. Content of 2 oxidation silicon 94% above. True density 2.35g/cm3. Have fight acid slag to erode performance. Higher high temperature intensity. Loading bate begins temperature 1670 ℃ of 1620 ~ . Use changeless form for a long time below high temperature. Thermal shock stability is low (hot exchange is 1~4 in water second) it is raw material with natural silica, adscititious and right amount mineralizer, in order to promote the quartz in base substrate quartz of translate into, scale. In the classics below reducing atmosphere 1430 ℃ of 1350 ~ are slow and firing. Heat to expand to the total volume that there is 1.5~2.2% about when 1450 ℃ , this kind of remains expands can make cut seam join closely, make sure build by laying bricks or stones builds body to have good air-tightness and structural strength, the loading bate temperature that says silica brick so issues highest melting point to be able to achieve 1750 ℃ above in the circumstance of 1620 ℃ .

Of the fireproof material of kiln of frit of furnace of the regenerator of open-hearth furnace of the partition of the char room that basically is used at coking plant furnace and firebox, steel-making and sedimentary room, soaking, glass and pottery and porcelain firing the vault of the kiln furnace such as kiln and other bearing place. The high temperature that also is used at hot-blast stove bearings place and roof of acidity open-hearth furnace.

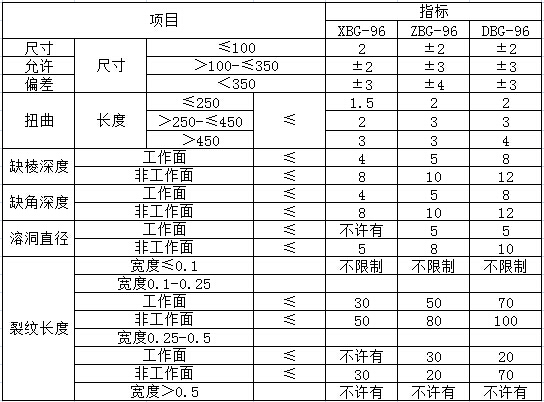

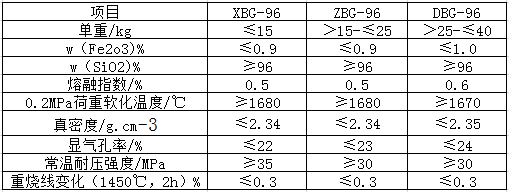

Vitreous kiln is JC/T615-1996 with standard of goods of high grade silica brick, the single heavy component that presses a brick is 3 brands: XBG-96, ZBG-96, DBG-96. Its

Manage changes target

Reach permissible variation in dimension to express as follows:

Vitreous kiln uses high grade silica brick

Manage changes target

:

Vitreous kiln asks with deviation of dimension of high grade silica brick and appearance (Mm)