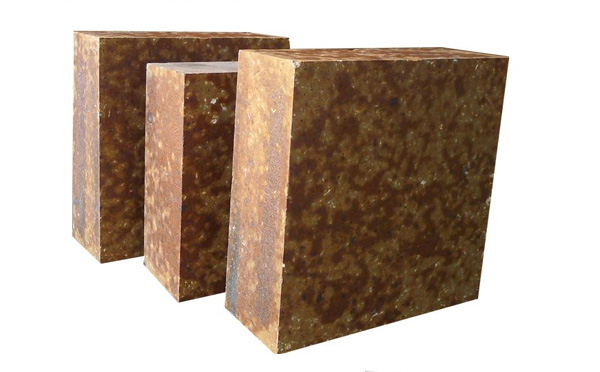

Silicon not brick, a kind of firebrick, have the homophonic of ” of “ wear-resisting brick, 90 time first try makes 20 centuries successful, ever called HMS tall wear-resisting brick, phosphate of wear-resisting coefficient prep above combines tall aluminous brick fivefold above. With respect to its substance appearance part is told should be goods of carborundum — Mo Laishi, abbreviation silicon not brick. This appellation is in mostly building materials industry is popular, other industry calls silica brick of tall aluminous carbonization, 3 oxidation commonly carborundum of 2 aluminous — brick.

Silicon not the brick is tall aluminous aluminous grog and carborundum the Al2O3-SiO2-SiC that makes for main raw material fastens fireproof material, sex of temperature of its loading bate, heatproof shake, wearability and fight the function index such as aggressivity brick of excel tall aluminium, good even Yu Jianjing stone brick. At present domestic cement rotary kiln is divided firing other position uses silicon almost besides the belt not brick. The article narrated silicon simply not manufacturing process of the brick.

Silicon not compact rate of the brick is very important, send the products with high density to be able to restrain the oxidation of SiC, raise silicon not integrated specifications of the brick. The density of the goods of grain class conjugate of pug has immediate effect. Deliver density product high to obtain, calculate by Dinger-Funk formula, seek the number of concentration percentage by volume that gives all sorts of size. The per cent that reachs according to raw material density granuality is comprised again, do through the experiment adjust appropriately, produce the grain grading of need so that be born.

Dinger-Funk formula:

CPFT/100 = Dn-Dsn/D1n-Dsn

In type: CPFT is number of concentration percentage by volume of some granuality accumulative total / %;D1 is the largest particle size / Mm;Ds is the smallest particle size / Mm;D is random intermediate particle size / Mm;n is fine number of particle size distribution.

When D1= 5mm, d takes 3mm, 1mm, 0.5mm, 0.088mm, 010mm respectively, ds=0.0005mm, n is taken 0.37.

The density of all sorts of raw material presses a watch the composition of granuality of several estimation cipher out of 2. Want grain to pile up cheek by jowl already in actual production, should consider to shape again the agglomeration sex of the exterior of adobe and goods. Big grain removes framework action to take principal part in accumulation, if fine pink is too little, grain is mobile and bad, shape if difficult; is fine of pink fineness and insufficient, goods hard agglomeration, if fine pink quantity is too much,increase structural stoma; , shape generation layer is cracked, stomatic quantity increases in basic level, product volume density drops. Accordingly, on afore-mentioned formulary computation foundations, actual production uses grading of the following grain: 1)3? 5mm: 18%~19% ; 2)1-3mm: 29%~30% ;3)0.5-1mm: 13% ? 14%;4)0.088? 0.5mm: 21% ? 22%;5)0.010-0.088mm: 13%~14% ; 6)≤0.010mm: 5% ? 6% .

2.3 pug bond experiments

Same kind of recipe, same manufacturing technology (1390 ℃ are firing) , the bond of pug is different, the main physics index of goods is different, if express 3 kinds.

Phosphoric acid combines product not only the structure is compact, intensity is high, and loading bate temperature is high, wearability is good.

Carborundum and Mo Laishi of carborundum of production of tall aluminous aluminous grog accord with the engineering technology of firebrick goods to develop, because carborundum oxidation produces 2 oxidation silicon, with 3 oxidation 2 aluminous reaction form Molaishi (3Al2O3 ˙ 2SiO2) , can raise goods to cause density and strength, diaphragm is formed in goods surface, can prevent carborundum to oxidize further, make carborundum maintains certain content in firebrick of tall aluminous carborundum, the thermal shock stability that improves product, wearability, fight aggressivity. Excel in is compact silicon not the brick is divided on cylindrical shell of cement rotary kiln firing beyond the belt individually paragraph the service life of the belt raises 3~4 than tall aluminous brick times.

In recent years, silicon not firebrick gets rapid development in the application of cement rotary kiln, especially new-style the occurrence of dry method kiln and large change, intensity of the thermal stress inside the rotate speed of kiln, kiln rises substantially, qualitative to the material of fireproof material, manage changed function to raise new taller requirement. Because this cement rotary kiln is divided firing take the protection that hangs kiln skin in its to fall to still be outside use magnesium chromic brick, second firing belt, transfer belt, cooling zone is in convert silicon not after the brick, the effect is apparently good at magnesian chromic brick.

At present the province such as domestic Zhejiang, Jiangsu, Shandong, Shanxi has company of 10 several fireproof data to produce this kind of product. Because source of raw material of this kind of product is convenient, craft requirement is lax, each company is produced actually very can big, want to be able to produce argillaceous brick or tall aluminous firebrick can produce silicon only not brick. The product is begged for be more than, market competition is intense.

Next, silicon not the brick is had high temperature resistant, fight erode, fight wear away characteristic, do not cross the technical level difference as a result of each enterprise, product quality is different also. How to produce the silicon with high quality not brick, raise cement kiln to use the service life of fireproof material, make here some discuss, produce and not use reference of the brick for silicon.

As silicon not the progress of firebrick engineering technology, the quality of its goods gets rising significantly, specifications also has rise substantially. Differ to get used to cement rotary kiln the use condition of place, silicon not firebrick also is many brands by the single brand development in the past.

(1) goods structure is compact, wearability is good.

Silicon not firebrick advocate brilliant photograph by the mineral corundum with tall hardness (Mohs hardness 9.0~9.2) , carborundum (Mohs hardness 9.0~9.5) , Molaishi (composition of Mohs hardness 7.0~7.5) . Goods structure sends density tall, bulk density general is ubiquitous 2.7~3.0 G/cm3. Look for fireproof data network to consult according to the data, the function of normal temperature wear-resisting of fireproof material depends on the compact sex of its intensity and structure, intensity and send the material with high density, wear-resisting performance is better. Liner of cement rotary kiln suffers the scroll of stock for a long time to grind, wearing away is one of main reasons that fireproof material liner mars. Silicon not of firebrick send density, intensity and wearability remarkable excel is fought flake tall aluminous brick reachs brick of magnalium pointed spar. Silicon not firebrick is in cement rotary kiln second firing it is belt, good to cross the place such as screen to use the effect, can say wearability is good the effect with rose very main.

(Temperature of 2) loading bate is high, high temperature capability is good.

Silicon not loading bate temperature of the brick is in above of ℃ of 1 450, ℃ above of highest 1 650. The temperature of goods loading bate of different brand has certain difference. The different position firebrick of liner of cement rotary kiln face temperature is different, second firing belt, before transfer take temperature to amount to left and right sides of 1400 ℃ , prep above is firing take firebrick face temperature (because of firing contain kiln skin protection, firebrick face temperature is) of ℃ of 900~1 000. Also exceed what often use to fight with respect to the index of loading bate temperature of these bricks flake tall aluminous brick is mixed firebrick of phosphatic tall aluminium (loading bate temperature is) of ℃ of 1 300~1 520.

With firing take photograph comparing, transfer because the belt is protected without kiln skin, get easily reducing atmosphere and thermic load the influence that wait, its service life is the bottleneck problem of cement rotary kiln all the time, because plant of this a few cement is in,transfer belt introduce product of magnalium pointed spar. According to some factory 5 000 T/d large cement rotary kiln transfers belt with magnalium needle spar brick considers to reach: Transfer before belt with magnalium needle spar firebrick is not had basically erode, but be as a result of alkaline deposit in open pore, make a structure compact change, cause form with a firebrick differ paragraph of belt, and make firebrick hot the face flakes and produce cranny, cause liner to mar. And silicon not firebrick because itself structure is compact, the face forms special firebrick successive SiO2 compact layer, prevent melt material to permeate, chemistry of together with Al2O3, SiC, SiO2 is stable, do not produce severe reaction with the gas such as the SO2 of the generation inside kiln, O2, CO2, do not produce chemical reaction with cement stock, because this is fought,erode ability stronger. It is silicon next not thermal shock stability of the brick is good. Because silicon not contains the SiC of certain amount in the brick, well-known, siC thermal conductance is tall, hot coefficient of expansion is smaller, make the thermal shock stability of goods rises significantly, experiment of water-cooling of 1100 ℃ is in 10 times above, highest amount to 46 times, because this cement rotary kiln uses silicon not the brick does not flake, do not rupture, can improve service life significantly.

(3) drops kiln body temperature, heat proof quality is good.

Silicon not 〕 of K) of ˙ of 2.3~2.5 W/(m of thermal conductance 〔 is more alkalescent 2.69 ~ of goods 〔 〕 of K) of 2.74 W/(m ˙ is low, because of this silicon not adiabatic effect of the brick is better. In large rotary kiln second firing belt, transfer end of belt, warm-up belt, kiln, tertiary air canal, decompose the place such as furnace to use silicon not brick, compare with alkalescent brick photograph, temperature of cylindrical shell surface reduces above of 100 ℃ .

Silicon not the bricky application in cement rotary kiln

The silicon that our country produces not brick, the 2000~10000 T/d that designs in domestic proper motion got applied extensively on large cement rotary kiln. As we have learned, some kiln cylindrical shell besides long those who make an appointment with 20 M is firing belt with direct union left and right sides of each 0.8 M uses opening of kiln of brick of magnesian sth resembling a net, around pouring outside makings, use silicon entirely not brick. Firing of the belt hind, so called second firing belt, general with firing the area is same, with brick of direct union magnesian sth resembling a net, but kiln skin is stabilized very hard. Because stability of thermal shock of brick of magnesian sth resembling a net is poor, fight grind intensity low, brick and part of kiln skin union follow kiln skin easily to flake, affect this paragraphs service life, and silicon not the brick is good as a result of thermal shock stability, use process does not rupture, do not flake, fight erode, service life is lengthened apparently. For example: 21.55 M~24.955 M of rotary kiln of cement of 2500 T/d of company of cement of river of Shun of Zhejiang beyond Yao uses chromic brick of direct union magnesium formerly, service life 310 days, convert silicon not brick (AZM1650) , service life amounts to rotary kiln of cement of 2500 T/d of group of mining industry of north of the Huaihe River of Anhui of 410 days of; second burn belt use magnalium needle formerly spar brick, transfer belt use formerly fight flake tall aluminous brick, inside a year rush to repair changes a brick to be amounted to 3 times, appear the most shortly in 3 months red kiln. And line of new configuration kiln, second firing belt convert silicon not brick 1680, transfer belt for silicon not brick 1650, the service life of kiln is as long as 15 months. Of the 2 500t/d kiln that Ningxia surpasses golden cement company transfer the place such as the belt uses silicon not brick already 7 many months, did not discover any problems, still in use.

Silicon not the bricky application in cement rotary kiln

Cement rotary kiln transfers the bricky face temperature of the belt is controlled in ℃ of 1 400, the temperature of the place such as warm-up belt, cooling zone is taken than transferring should low, it is firing take skin sufferring kiln to protect, the temperature of bricky face is not high also, silicon not loading bate of the brick begins temperature to be in above of ℃ of 1 500, especially goods structure is compact, by hardness tall mineral, corundum, carborundum, Molaishi is comprised, wearability is particularly good, it is to transfer the ideal brick of the belt is planted. Compression intensity and carry on one's shoulder spend bate temperature apparent prep above is fought flake tall aluminous brick, stability of its thermal shock, corrosion resistance, wearability good, thermal conductance is not tall, just about hind transfer take craft character place to ask, service life is to fight flake bricky 1.5~2 times. Wearability suits cooling zone more very much, service life can amount to two years of above, the 3 ~ that are life of tall aluminous brick 5 times. Had differred by rotary kiln now the use condition of paragraph of belt, the silicon that applies different name function to differ not brick.

In addition, silica brick of tall aluminous carbonization is in the branch such as steely, nonferrous metal, chemical industry applies extensively also.